Page | 92

24.

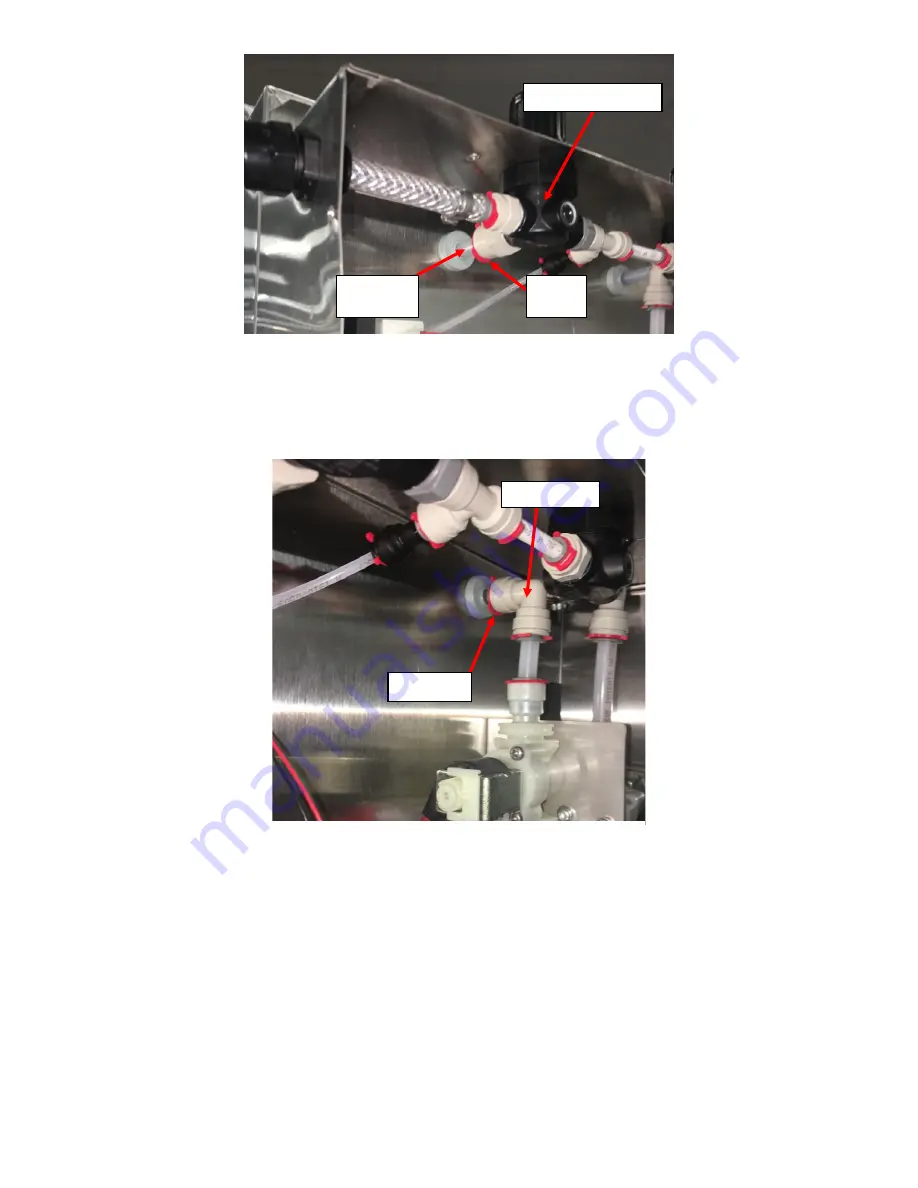

Turn the Solenoid Sub Assembly so that the Elbow attached to the subassembly is aligned with the Barrier Tubing

protruding from the Sealing Gray Grommet on the right and push the Elbow firmly to insert the tube into the Elbow

and install Locking Clip.

See Figure L26.

25.

Secure the Rear Enclosure in place by screwing in five Self Tapping #10-16 Screws

with a 5/16” Hex Drive

Screwdriver through the TOP TWO SLOTs OUTSIDE THE REAR ENCLOSURE and all FOUR SLOTS INSIDE THE REAR

ENCLOSURE, See Figure 13 and Figure 14. Ensure that Blue Barrier Hose is not bent during the process. If the Blue

Barrier Hose is bent during the Rear Enclosure Installation process, remove the Rear Enclosure and the Blue Barrier

Hose. Discard the Blue Barrier Hose and replace the Barrier Hose with a new/unused hose.

See Figure L27 and

Figure L28.

Left Pressure Regulator

Blue Barrier

Hose

Locking Clip

Elbow Fitting

Figure L26: Elbow on Solenoid/Flowmeter Assembly inserted into

Barrier Tube on the Right of Enclosure with Locking Clip installed.

Figure L25: Left Tube inserted into the Left Regulator with Locking Clip Installed.

Locking

Clip

Summary of Contents for JoeTap NITCOM

Page 55: ...Page 55 Appendix C JoeTap NITCOM 110V Wiring Diagram ...

Page 56: ...Page 56 Appendix D John Guest Speed Fit Guide ...

Page 79: ...Page 79 Appendix J Fridge Functionality Maintenance and Troubleshooting Guide ...

Page 80: ...Page 80 ...