6-4

Hydraulic System

When servicing the hydraulic system it is critical to

keep any dirt or debris from getting into the system.

Clean off all parts before disassembly and assembly.

When any of the hydraulic parts are disconnected

or removed or when the oil is changed, air must

be bled from the system. If air is entrained in the

system, loss of power, excessive heat, and damage

to the hydraulic pumps may occur. WARNING: Fluid

escaping under pressure may have sufficient force

to penetrate skin and cause serious injury. If fluid

is injected into the skin, seek immediate medical

attention. Keep body and hands away from pin holes

or nozzles that eject fluid under high pressure. If a

leak occurs, have the machine immediately serviced

by a trained technician. Never use hands to search

for hydraulic leaks. Use paper, cardboard, or UV dye.

Keep body and hands away from pin holes or fittings

that eject hydraulic fluid under high pressure.

Bleeding Air from the Hydraulic System

If air is entrained in the system, loss of power,

excessive heat, and damage to the hydraulic pumps

may occur. The cause of air in the system can be

from a leaking hose pulling in air or after replacing a

major component.

1. Fill the reservoir.

2.

Lift the machine so that the rear wheels are off

the ground. Be careful to support the machine

so that it will not fall or tip while the system is

bled of air.

3. With the bypass valves open and the engine

running, slowly move the control levers back

and forth five or six times.

4. Now close the bypass valves and with the

engine running, slowly move the control levers

back and forth five or six times.

5. It may be necessary to repeat the above steps

until all the air is purged and the rear wheels

are turning at normal speed.

6. After purging is complete, adjust the oil level in

the reservoir if necessary.

Checking oil

1. Ensure mower is on a level surface.

2. Lift hinged pad to access the sight-glass

3. Oil should be at the center of the sight-glass.

Filling oil

1. Lift hinged pad and remove vent cap.

2.

Use a funnel to fill tank

Changing Oil

1.

Remove filter from tank and allow the oil to

drain from the tank into a catch pan.

2. It is not necessary to drain the oil from the

pumps and motors unless a total purge is

required. Draining the oil from the pumps and

motors introduces air into the system and opens

the system for contamination.

3.

Using a new filter, oil the gasket and hand

tighten. Note this machine uses a non-bypass

suction filter; do not cross reference a standard

automotive pressure filter.

4.

Using a funnel, fill tank until oil reaches the

center of the sight glass.

5. Start the machine and allow the system to warm

up. Check level and top up as necessary.

6. DO NOT USE OIL NOT APPROVED FOR

YOUR MACHINE. Hydraulic and transmission

oils will damage your system, void your

warranty, and are not made for a hydrostatic

system. Use Mobil 1 15W-50.

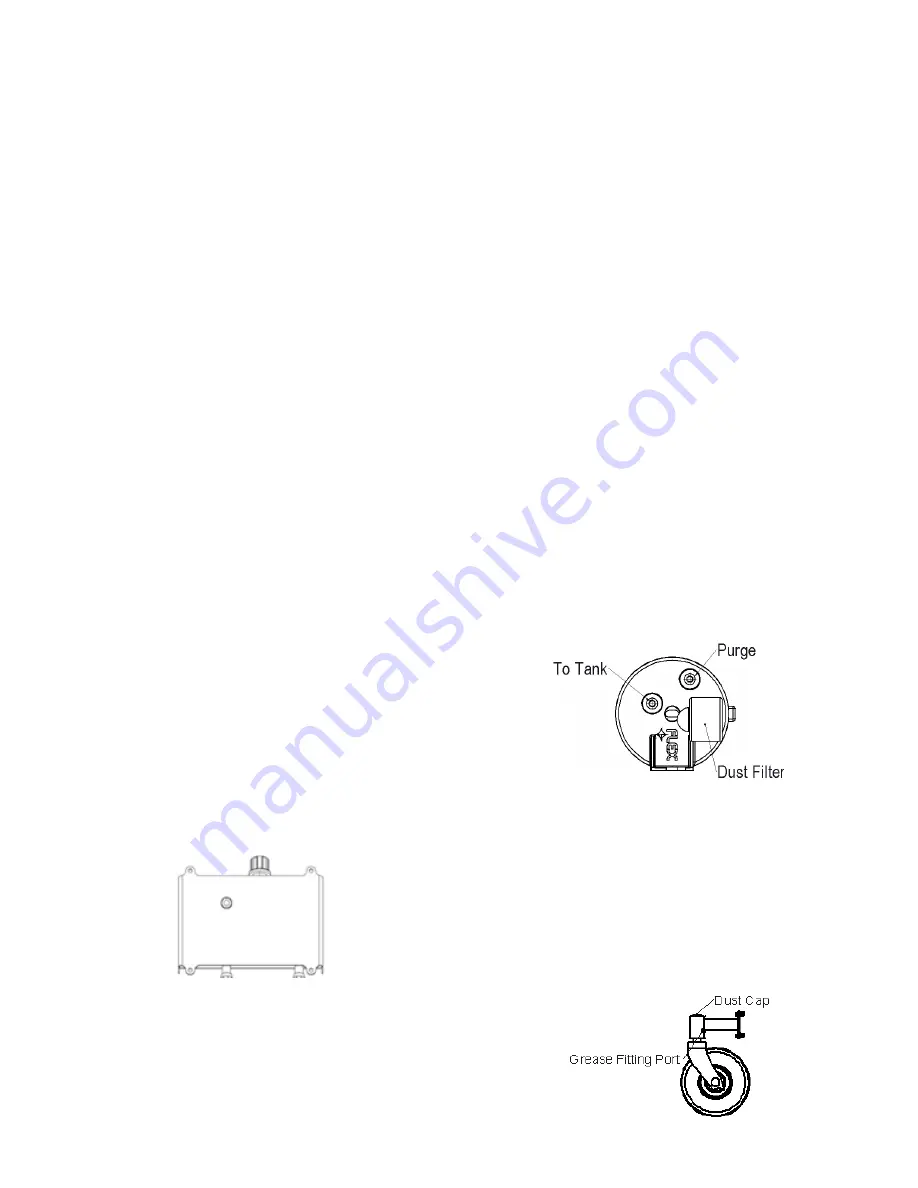

Fuel Evaporation System

All Wright Standers need to have this mandatory

feature.

•

Do not alter or remove.

•

Do not fill past the “Max Fill Level” line.

•

Over-filling could result in clogging the roll-over

vent and/or contaminating the purge canister.

•

The vapor canister is located under the dash.

•

Inspect and clean dust filter every 500hrs or

annually.

Lubrication

Your machine is made with sealed bearings and

synthetic dry lubricant bushings; therefore only the

front caster pivots need to be greased. Grease yearly

by either, removing the ¼-28 bolt and install a grease

fitting or by removing the dust cap, disassembling

and re-packing the wheel bearings. Use Mobil

Polyrex-EM grease. Use care filling with grease gun

as too much pressure could blow out the grease seal.

When re-installing dust cap, use two drops of thread

locker to prevent the dust cap coming off during

operation.

Sight Glass