Maintenance

5552

−

2/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

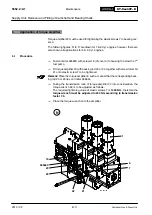

3.

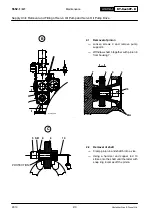

Removal of bearing shells

⇒

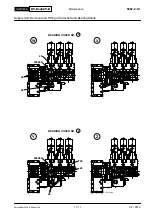

Loosen elastic screws 7 to bearings No. 2 3 4 and remove the bearing

covers (Fig. ’C’).

⇒

Place assembly template 94567 on an upper bearing shell (Fig. ’D’).

⇒

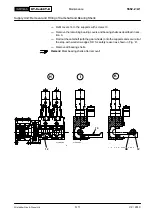

Press camshaft 12 accordingly by means of wooden underlay ’HU’ so that the

upper bearing shell can be turned downwards with the assembly template at

the same time (Fig. ’E’).

⇒

Remove the assembly template, the relevant bearing shell and then all other

ones.

Remark:

Mark bearing shells after removal!

D

012.982/05

012.983/05

I

I

II

II

I

I

X

94567

HU

I - I

II-II

7

17

94567

E

12

Supply Unit: Removal and Fitting of Camshaft and Bearing Shells

V2 / 2013

Summary of Contents for WARTSILA RT-flex58T-D

Page 8: ...Intentionally blank ...

Page 10: ...Intentionally blank ...

Page 12: ...Intentionally blank ...

Page 14: ...Intentionally blank ...

Page 20: ...Intentionally blank ...

Page 32: ...Intentionally blank ...

Page 58: ...Intentionally blank ...

Page 66: ...Intentionally blank ...

Page 72: ...Intentionally blank ...

Page 84: ...Intentionally blank ...

Page 88: ...Intentionally blank ...

Page 92: ...Intentionally blank ...

Page 120: ...Intentionally blank ...

Page 122: ...Intentionally blank ...

Page 124: ...Intentionally blank ...

Page 132: ...Intentionally blank ...

Page 136: ...Intentionally blank ...

Page 148: ...Intentionally blank ...

Page 152: ...Intentionally blank ...

Page 156: ...Intentionally blank ...

Page 168: ...Intentionally blank ...

Page 176: ...Intentionally blank ...

Page 186: ...Intentionally blank ...

Page 192: ...Intentionally blank ...

Page 196: ...Intentionally blank ...

Page 200: ...Intentionally blank ...

Page 214: ...Intentionally blank ...

Page 234: ...Intentionally blank ...

Page 238: ...Intentionally blank ...

Page 242: ...Intentionally blank ...

Page 256: ...Intentionally blank ...

Page 264: ...Intentionally blank ...

Page 272: ...Intentionally blank ...

Page 280: ...Intentionally blank ...

Page 282: ...Intentionally blank ...

Page 290: ...Intentionally blank ...

Page 296: ...Intentionally blank ...

Page 300: ...Intentionally blank ...

Page 312: ...Intentionally blank ...

Page 314: ...Intentionally blank ...

Page 318: ...Intentionally blank ...

Page 334: ...Intentionally blank ...

Page 340: ...Intentionally blank ...

Page 348: ...Intentionally blank ...

Page 352: ...Intentionally blank ...

Page 356: ...Intentionally blank ...

Page 358: ...Intentionally blank ...

Page 362: ...Intentionally blank ...

Page 366: ...Intentionally blank ...

Page 370: ...Intentionally blank ...

Page 380: ...Intentionally blank ...

Page 384: ...Intentionally blank ...

Page 386: ...Intentionally blank ...

Page 392: ...Intentionally blank ...

Page 402: ...Intentionally blank ...

Page 412: ...Intentionally blank ...

Page 414: ...Intentionally blank ...

Page 438: ...Intentionally blank ...

Page 440: ...Intentionally blank ...

Page 444: ...Intentionally blank ...

Page 454: ...Intentionally blank ...

Page 498: ...Intentionally blank ...