21

Operations

1.

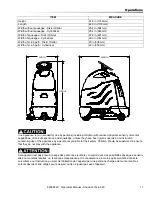

Squeegee Latch

The squeegee latch holds the squeegee in place.

2.

Squeegee Hose and Tube

The squeegee hose and tube carry the recovered solution to the recovery tank.

3.

Squeegee Wheels

The squeegee wheels support the squeegee at the correct height and angle to automatically obtain optimum

suction.

4.

Double Scrub Support Cable

The double scrub support cables retain the deck in the double scrub position.

5.

Double Scrub Cable Hook

The double scrub cable hook is the connection point for the double scrub support cable.

Since the squeegee is raised and lowered by the scrub deck, the double scrub position is set manually.

86398220 Operators Manual - Chariot-2 iScrub 20

4

CYLINDRICAL

1

3

2

5