11

3180-10

60706-238

ELECTRIC STARTING (NG only)

When operating on NG, you will have to always use

the electric start to get the unit running. Because of

the engine vacuum need to activate the fuel system

it is almost impossible to manual start the unit using

NG.

1. Check oil level, refi ll as needed.

2. Turn on the NG fuel supply

3.

NEVER USE THE CHOKE WHEN OPERATING

ON

NG..

4. Turn the engine switch to the “on” position

5.. Operating the starter. Rotate the key switch

briefl y to the START position. The starter life is

improved by using shorter starting cycles with

time to cool off between cranking cycles. Do

not operate the starter more than 5 seconds and

wait at least 10 seconds before operating the

starter again, Repeat cycle if necessary.

6. When the engine starts, release the key

switch, allowing it to return to the “on” position.

7. The engine should promptly come up to

operating

speed.

STARTING HINTS

1.

Cold weather

a. Use the proper oil for the temperature

expected.

b. Use fresh winter grade fuel. Winter grade

gasoline is blended to improve starting. Do

not use summer grade gasoline.

2.

Hot weather

a. Use the proper oil for the temperature

expected.

b. Use only summer blended gasoline. Using

gasoline left over from winter may cause the

unit to vapor lock.

STOPPING AND STORAGE

1. Move the engine switch to the “OFF” position.

2. Turn off the fuel supply valve.

3. Before extended storage (over 30 days) certain

precautions must be taken to ensure the fuel

doesn’t deteriorate and clog the fuel system.

Note:

The use of a fuel additive, such a STA-BIL or

equivalent will minimize the formation of gum depos-

its during storage. The additive may be added to

gasoline in the engines fuel tank or to gasoline in a

storage container.

a. Add the fuel stabilizer to the fuel in the tank

and run the unit for 2 minutes to circulate the

stabilizer throughout the fuel system.

b. If you choose to remove the remaining fuel

from the fuel tank, it must be drained into an

approved

container.

c. Start the engine and allow it to run until all

the fuel in the carburetor and the fuel lines

has been used up and the engine stops.

Note:

Running the engine to use up the fuel in the

lines and carburetor will still leave a small amount of

fuel in the carburetor. It is best for extended storage

to treat the fuel before draining.

d. While the engine is warm, drain the oil and

refi ll with fresh oil.

e. Clean dirt and chaff from cylinder, cylinder

head

fi ns, blower housing, screen and

muffl er areas.

f.

Store in a clean and dry area.

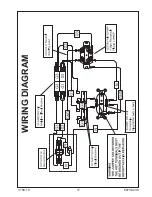

ON

MAX.

ON

MIN.

OPEN

OPEN

ENGINE SWITCH

ON

CLOSED

ON

MIN.