9

REV A

OPM-136

PRE-START CHECKS

WARNING: PERSONAL INJURY

When working on or around these generators, do not wear loose fitting

clothing or any articles that may get caught in moving parts.

1. Visually inspect the generator. Check for:

A. Correct mounting

B. Physical damage

C. Debris in cooling vents and screens (could cause generator to

overheat)

IMPORTANT: The manufacturer recommends that, if the generator

has been stored for any length of time, before using it, the operator

removes the control box cover and cooling fan screen. Then inspect

the generator for rodent nests or other objects that could cause the

generator binding and/or overheating. See “cleaning portion of the

Maintenance section.

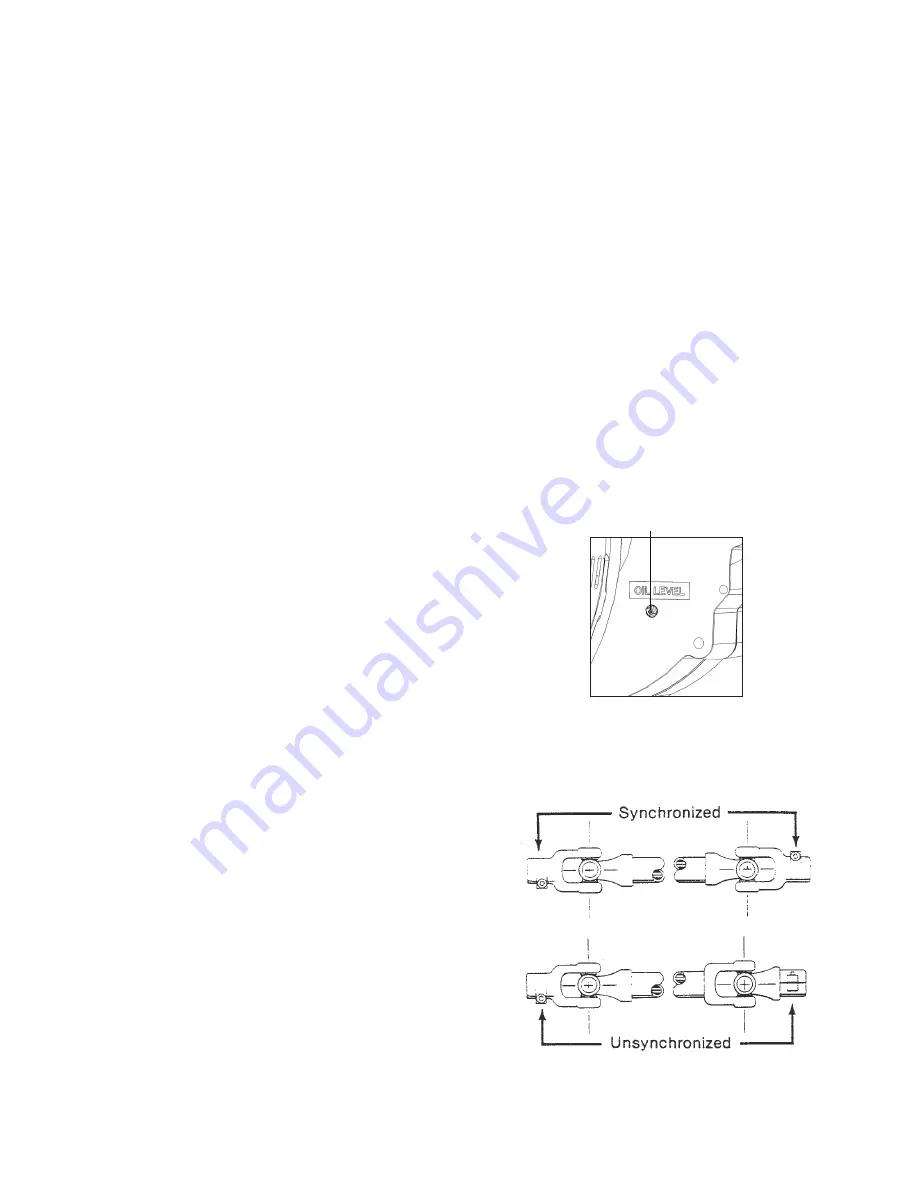

2. Check gearcase oil level by removing the plug located on the

backside of the gearcase marked “OIL LEVEL”. To refill oil, see

LUBRICATION in the MAINTENANCE section in this manual.

NOTE:

Either too little or too much oil can harm the equipment.

3. Make sure the drive shaft (tumbling bar) is assembled with its

universal joint knuckles “synchronized”. If the knuckles are not

synchronized, the bar will chatter when rotating, which will cause the

generator output voltage to flicker.

0" --

1

Oil Level Plug

Page 6

60706-199

1005-00

7. Check all electrical connections in the system to be ener-

gized by the generator. Make sure the connections are cor-

rect and are tight.

8. Make sure all loads are turned off. Do not start the genera-

tor under load.

GENERATOR STARTING PROCEDURE

1. With the power take-off drive disengaged, start the engine

which will drive the generator. Run the engine long enough

to warm it up before proceeding, so that it will run smoothly

and achieve full power under generator load.

2. With engine idling, engage the power take-off drive.

3. Watch the voltmeter on the generator and slowly increase

engine speed until the output reaches approximately 260

volts, in green portion of voltmeter scale.

4. With engine and generator running smoothly, switch on

the electrical load while watching the voltmeter.

NOTE: Equipment Damage

If the load includes motors turn them on one at a time, highest

starting current motor first, next highest second, etc.

Readjust engine throttle to keep generator output under load

at 240V (in green portion of voltmeter scale). If engine is

equipped with speed governor, it may automatically readjust

the throttle as the load changes and keep the generator output

at the proper level. However, some governors are not sensitive

enough to maintain proper output under changing load, and in

such cases the throttle will have to be manually readjusted .

GENERATOR SHUTDOWN PROCEDURE

1. Switch off electrical load.

2. Reduce speed of engine driving generator to idle.

3. Disengage power take-off drive, and allow generator to

coast to a stop.

WARNING: Personal Injury

Never try to manually stop the generator. Always let it coast

until it stops.

5. Shut off the engine.

4. Disconnect drive shaft (tumbling bar)

power take-off end first, then generator end.

Figure 6

Figure 7

3. Make sure the drive shaft (tumbling bar) is assembled with

its universal joint knuckles “synchronized,” as illustrated in

Figure 7. If knuckles are not synchronized, the bar will chat-

ter when rotating, which will cause the generator output

voltage to flicker.

DANGER: Personal Injury

POWER TAKE-OFF MUST BE DISENGAGED AT THIS TIME.

4. Couple the tractor to the generator with the drive shaft (tum-

bling bar). Couple the tumbling bar to the generator input

shaft first, then to the power take-off shaft. Check align-

ment, tractor, power take-off shaft (tumbling bar), and gen-

erator input shaft should form a straight (or nearly straight)

line, with less than 15° misalignment between the shafts.

Misalignment will cause generator output voltage to flicker.

CAUTION:

Make sure that all tumbling bar lock pins are engaged and

that all safety shields are in place before operating the PTO

generator.

5. Make sure no binding exists in generator or gear box. If

binding is found, locate the cause and correct it before pro-

ceeding.

6. Make sure that the electrical loads to be driven by the gen-

erator will not draw more current than the ratings of the

generator receptacle or cord set which will supply the cur-

rent.

OPERATION

OUTPUT POWER AVAILABLE AND LOAD DETERMINATION

Before using the generator, read and understand the following

information.

Generator output current (amperage) is internally limited by three circuit

breakers. If too much demand is placed on a generator output (if you

try to drive too many motors with it, for example), one of the circuit

breakers will trip, cutting off the output in order to protect the generator.

A 20 Amp push-to-reset circuit breaker protects the 120V duplex

receptacle output circuit. 20 Amps is the total limit for both outputs

of the duplex receptacle. The 480V is equipped with the Anderson

receptacle only.

A 50 Amp toggle circuit breaker protects the 240V receptacle output

circuit. The 480V is equipped with the Anderson receptacle only.

A large two pole (three pole for three phase) switch type main circuit

breaker protects the generator windings and output circuits, including

the load disconnect receptacle outputs. The load disconnect receptacle

is the largest gray receptacle on the generator output panel.

To aid in determining how much load can be applied to the generator,

and how it should be distributed among the generator output

receptacles, the following formulas may be useful. Get load voltages,

current, and wattage from the nameplates on the equipment in the

load.

Load current (in Amps) x Load voltage = Load wattage

Amps x Volts = Watts

Watt/1000 = kW

Load wattage / Load voltage = Load current (in Amps)

Example: 250W, 120V floodlight load: 250W / 120V = 2 Amps

NOTE:

Electric motors require more current to start than to run. Commonly,

the current rating given on a motor nameplate is the full load (running)

current required by the motor, not its starting current, which is a lot

higher. Motor starting current requirements vary greatly, by motor size

and type. Repulsion-induction type motors are the easiest to start,

typically using 1 1/2 to 2 1/2 times as much current to start as to run.

Capacitor type motors usually require 2 to 4 times as much current

to start as to run. Split-phase type motors are the hardest to start,

normally using 5 to 7 times as much current to start as to run.