Section VES-R00-20A

030-101639 Rev. B

R

4

0802IARB

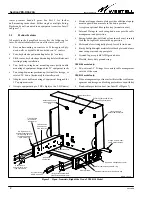

tect the mounted equipment. A centered slot near the front

edge of the top flange accepts a matching lock tab on the lock-

ing front cover, for the VESR-14 model only. A rectangular

small hole on each side flange serves as a latch-catch for the

slam-bolt latch on each swing-arm. A few tie-down slots on the

lower portion of the back plate facilitate cable management.

2.1.3

Ground Lug and Ground Strap

All models come equipped with both a ground lug and a ground

strap. The ground lug is located at the bottom right corner of

the back plate, and accepts a #6 AWG ground wire. Use a

slotted or blade screwdriver to loosen the lug’s set screw, insert

a company-approved ground wire into the space provided un-

der the screw, then tighten the set screw, all per company

practice. For added safety, a factory-installed ground strap

bonds the metallic back plate to the metallic arms of the Swin-

gRack.

2.1.4

Swing-Arms

Arm Design and Function.

A set of sturdy but light-weight alumi-

num swing-arms, one on each side of the SwingRack, imitate

the horizontal spacing between the rails of a 23" equipment

rack, to allow the SwingRack to accept any equipment designed

for 23" rack mounting (equipment designed for 19" racks is

mounted using the adapter ears, explained in Paragraph 2.1.5

below). Each arm is attached to the lower outside corner of the

back plate, and rotates 90

_

from the up or vertical position to

the down or horizontal position. The up position is used after

the equipment is mounted and placed in service, which keeps

the equipment flush against the wall and out of valuable aisle

space in the equipment room or lab. The down position facili-

tates equipment mounting on the SwingRack as well as testing

and maintenance that may require visual and hand access to

front panel options, LEDs, connectors, etc.

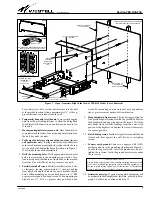

Arm Features.

A set of four holes at the end of each arm enables

the installer to attach the adapter ears. Provided in each arm of

each SwingRack unit are either two or three internal D-rings,

a slam-bolt latch, a cable access hole, several cable tie-down

slots or holes, and threaded holes for mounting an optional

splice tray in either arm. Horizontally connecting the arms to-

gether is a cross piece, the support plate. In the VESR-14

model only, a feature set, which includes a flexible protection

tube, a cable management spool, a cable race-way or duct, and

two fiber cable protection boots, provides additional, conve-

nient, fiber cable management.

2.1.4.1

Internal-Arm D-Rings

Inside the channel of each swing-arm are either two or three

factory-installed D-rings (depending on the model ordered).

Four sets of holes are distributed in the swing-arms, and each

D-ring populates one set of holes. The rings are factory

installed, yet can be detached and moved to a different posi-

tion, if desired. The rings are made of a flexible aluminum, and

are designed with an angled cut or slit on the outer edge to facil-

itate cable routing, ingress, and egress into and out from the

internal confines of the D-ring. Simply press on the top or bot-

tom half of the D-ring and route the cables through the

provided gap in the D-ring.

2.1.4.2

Slam-bolt Latch

When the swing-arms are in the up position, a slam-bolt latch

firmly secures the arms to holes in the side flanges of the back

plate. To release the latches and lower the arms, pull or slide the

protruding knobs of the latches inward, toward the center of

the unit. Always maintain hand contact with both swing-arms

during and after latch release, and gently lower the arms to the

down position. Do not allow the arms to free-fall to the down

position.

2.1.4.3

Support/Name Plate

Halfway down each arm, a wide support plate is factory-at-

tached to each arm. In addition to providing joint-arm unity

and cross-stability to the arms, it doubles or serves as a horizon-

tal bottom support for equipment during equipment mounting

in the SwingRack, and triples as the equipment name plate.

2.1.4.4

Cable Access Holes

For convenience and safety, a cable access hole is provided

near the back of each swing-arm. Routing cables through this

hole helps prevent accidental cable damage near the rotating

arm-to-back-plate joint. Always lower the arms slowly and

verify that any cables are either routed through the access hole

or otherwise secured but free and clear of potential damage

from moving parts. The protective flexible tube, provided with

the VESR-14 model and described in Paragraph 2.2.1, also

serves to protect cables.

2.1.4.5

Cable Tie-down Slots and Holes

In the inside wall of each arm are two types of tie-down slots or

holes, for cable management. The narrow tie-down slots are

typically used to secure cables which are routed and located

closer to the center area of the SwingRack. The larger tie-down

holes are typically used to secure cables located

within

the arm

channels, facing the exterior sides of the SwingRack.

2.1.4.6

Area for Optional Splice Tray

When viewing the SwingRack with the arms in the down posi-

tion, an optional and separately ordered kit containing two

screws and a splice tray can be mounted within the channel of

each swing-arm, between two of the D-rings and above the

slam-bolt latch. Two holes in the arms accept the screws, which

secure the splice tray in place. See Table 3 or call Westell for

more information on this kit.

2.1.5

23"-to-19" Adapter Ears

Equipment designed for mounting in 19" equipment racks can

be easily mounted in the SwingRack by installing either two or

four of the four provided adapter ears on the ends of the swing-

arms. These adapter ears convert the 23" wall-mount

SwingRack to a 19" wall-mount SwingRack. When mounting

equipment with a rack height of 1 Rack Unit (1 RU, or 1.75"),

install two of the adapter ears, one at the end of each swing-

arm. When mounting equipment which is 2 RUs high, install all