Section VES-R00-20A

030-101639 Rev. B

R

7

0802IARB

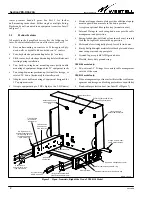

Figure 7.

Open, Isometric, Right-Side View of VESR-14 Model (Cover Removed)

Wood studs, 16”

on centers

(for

drywall applications)

Plywood, drywall, or

concrete wall

Center

mounting

hole

(used to

self-level the

unit)

Corner mounting hole*

(4 total)

Cover

(VERS-14 model only)

* Mounting screw heads must fit through

the large round part of the keyholes

Cable Race-way

(slotted duct)

(1 RU high,

VESR-14 only)

Snap-on

cover

Enlarged view of Bend Radius Protection

Boot

(guide fiber cables through the slots)

Inset A

Inset B

(VERS-14 only)

External D-rings mount at center

holes (see Figure 8 & Figure 8)

Wall of

SwingRacks, 3 high.

Inset C

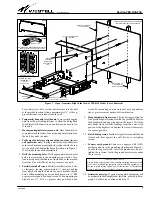

heavy-duty screw, bolt, or other wall-fastener into the wall

at the marked location. Allow approximately 1/4" of the ap-

proved fastener to protrude from the wall.

4.

Temporarily hang and level the unit.

Temporarily hang the

unit from the protruding fastener to allow the SwingRack

to self-level itself. If desired, a hand level can be used to lev-

el the unit.

5.

Mark mounting-hole locations on wall.

Once the unit is lev-

el, quickly mark the other, four, mounting hole locations on

the wall. Set aside the unit.

6.

Verify marked holes are aligned with wood studs

(for dry-

wall applications only).

If using a wall with a drywall surface,

ensure each marked mounting hole is aligned with the cen-

ter of a wood stud behind the drywall, as shown in Figure 7.

If not, make the needed adjustments.

7.

Drill the mounting holes.

Drill appropriately-sized pilot

holes, to accommodate the mounting screws, bolts, or fas-

teners being used (hardware not included), at the marked

locations.

Do not drill holes too big, to ensure a snug fit

.

8.

Partially install all screws.

Partially install all screws, bolts,

or fasteners, leaving approximately ¼" inch protruding

from which to hang the unit via the unit’s keyhole-shaped

holes. When mounting on a wood backboard, use ¾" #10

or greater steel pan-head wood screws. When mounting on

drywall, use 1¼" #10 or greater steel pan-head wood

screws. For mounting on a concrete wall, use an equivalent

size or greater cement anchor/bolt combination.

9.

Hang SwingRack from screws.

Lift the unit again, align the

four protruding wall fasteners with the predrilled holes in

the SwingRack, and hang the unit on the screws. Verify the

unit hangs freely (without binding) from the narrow top

portion of the keyholes, and adjust the screws if necessary

to ensure a good fit.

10.

Finish driving screws.

Finish driving all screws until the unit

is flush and firm against the wall. Do not over-tighten

screws.

11.

Connect earth ground.

Connect an approved #6 AWG

earth ground wire to the ground lug (lug shown in Figure 4).

Loosen the lug’s set screw, insert the ground wire, and re-

tighten the set screw. Verify the ground wire is secure under

the set screw.

- GROUNDING NOTE -

Always follow safety precautions, standard operating procedures and

local codes for grounding equipment when installing, upgrading, re-

pairing or maintaining equipment. All instructions or information

herein is subordinate to local codes, operating procedures or practices.

12.

Determine next step

. If customer-supplied equipment will

be mounted in the SwingRack at this time, proceed to Para-

graph 3.5; otherwise, continue with Step 13.