Section VES-R00-20A

030-101639 Rev. B

R

3

0802IARB

Figure 4.

Closed View of VESR-14 Model (without cover)

Locking cover

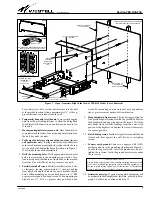

Figure 5.

Closed View of VESR-14 Model (Includes Cover)

Ground strap

Ground lug

Support/Name plate

Adapter ears

(for installation of 19” equipment)

Latch-release

knob

Cable access

hole

S

Protective cable race-way (slotted flexible duct, mounts

from one arm-end to the other)

S

Flexible, orange, fiber-cable protection tube protects

cables as they enter the wall-mount rack

Feature / Option

VESR-00

VESR-14

Back plate, with 5 keyholes

n

n

Two 90

_

swing-arms

n

n

Name / Support plate

n

n

Adapter ears, for 19”

4

4

Internal-arm D-rings

6

5

External-arm 3” D-rings

2

Locking Front Cover

n

Flexible Fiber Protection Tube*

n

Fiber Management Spool*

n

Cable Race-way (duct)*

n

Bend Radius Protection Boot*

2

Ground Strap

n

n

Ground Lug

n

n

Accepts optional splice tray

n

n

n

= equipped. * Asterisked features facilitate fiber cable management and protection.

Table 1. Options and Features of SwingRack Models

2.

FEATURES AND OPTIONS

Westell offers two versions of the SwingRack, as shown in

Table 1. Each model contains a different feature subset and op-

tion package. This section groups and describes the features that

are common to all models, the fiber management and protection

features, and other options which make each model unique.

2.1

Common Features

The features described in Paragraphs 2.1.1 to 2.1.5 below are

common to all models in the series.

2.1.1

Construction, Design, and Material

The one-piece SwingRack takes advantage of the available and

vacant wall space in crowded equipment rooms, so 1 or 2 RU-

high equipment that typically is mounted in 19" or 23"

equipment racks can be mounted on a wall, leaving valuable

rack space for taller equipment or additional equipment. Each

SwingRack model consists of a durable, steel, specially-de-

signed and molded back plate and two, aluminum, opposing

and symmetrical, swing-down rails or arms attached to the back

plate, each of which are further described below. The painted

surface is attractive and protective.

2.1.2

Back Plate

The steel back plate is the biggest component of the Swin-

gRack. It contains five recessed, predrilled, keyhole-shaped

mounting holes placed in a rectangular pattern; a top row of

three and a bottom row of two. The outer or corner holes in the

rectangular pattern are 16" apart horizontally, to accommo-

date walls containing wood studs which are 16" apart, on

centers. The keyhole shape of each hole allows easy mounting

by hanging the SwingRack on pre-installed mounting screws or

fasteners whose heads can fit through the large-diameter area

of the keyholes. For faster installation, the SwingRack can be

self-leveled" by temporarily and initially hanging the unit

from the center hole on a single centered wall-fastener, then

marking the remaining four mounting hole locations. The re-

cessed keyholes keep the heads of the wall fasteners from

contacting any equipment mounted in the SwingRack. The

wide, 90

_

, top and side flanges on the back plate serve to pro-