40

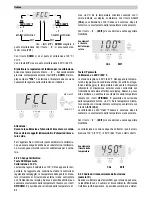

6. USB Interface

The WD 2M control unit is equipped with a Mini USB inter-

face as standard. This can retrofitted on the WD2 control unit

(See Page 171). WELLER standard software (CD is included

in scope of supply) has been provided to use the USB inter-

face). This software contains a firmware updater and moni-

tor software.

The firmware updater can be used to carry out a software

update, whereby the control unit can be provided with the

most up-to-date operating software.

The monitor software can be used for remote control of the

unit. Temperature curves can also be presented graphically,

printed out and saved.

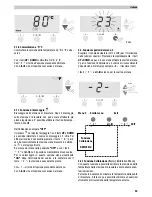

7. Potential balance

Due to the different circuits in the 3.5 mm switch jack sok-

ket (8), 4 variations are possible:

Hard-earthed:

without plug (delivery status)

Potential balance

with plug, balance line at

(impedance 0 Ohm):

middle contact

Potential-free: with

plug

Soft-earthed:

with plug and soldered resistor.

Earthing via selected resistance

value.

8. Operating guidelines

During the first heating-up period, coat the selected tinnable

soldering tip with solder. This removes oxide layers and con-

tamination on the soldering tip caused by storage. Never use

an aggressive flux.

The transition between heating element/sensor and the sol-

dering tip must not be impaired by dirt, foreign bodies or

damage because this would affect the accuracy of the tem-

perature control.

Handling the soldering tips

●

Select as low a working temperature as possible

●

Select the largest possible soldering tip form for the

application

Rule of thumb: approx. as big as the soldering pad

●

Guarantee a large-surface heat carriage between solde-

ring tip and solder joint by properly tin-plating the solde-

ring tip.

●

Before long work breaks, switch the soldering system

off, or use the Weller function for temperature decrease

when not in use.

●

Coat the tip before placing the soldering iron in the rest.

●

Apply solder directly to the solder joint and not on the

soldering tip.

●

Use the corresponding tool to change the soldering tips.

●

Never apply mechanical force to the soldering tip.

9. Accessories

005 13 173 99

WMRP soldering iron handpi-

ce (without soldering tip)

005 27 028 99

Pre-heating plate WHP 80

005 29 178 99

Soldering iron set WSP 80

005 29 179 99

Soldering iron set WMP

005 31 185 99

USB Extension module

005 33 113 99

Soldering iron set LR 82

005 33 131 99

Soldering iron set MPR 80

005 33 133 99

Desoldering set WTA 50

005 33 135 99

Soldering iron set WSP 150

WMRH

Soldering iron holder for WMRP

WMRT

Desoldering set

WPHT

(WMP) Switching holder

WPH80T

Switching holder (WSP 80)

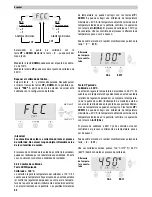

10. Scope of supply

WD 2

WD 2M

Control unit

Control unit

Mains cable

Mains cable

Jack plug

Jack plug

Operating instructions

Operating instructions

Safety information

(CD)

Safety information

(CD)

USB cable

Soldering tips 165-169

Exploded drawing WD 2, see page 172

Circuit diagram WD 2, see page 173

Exploded drawing WD 2M, see page 174

Circuit diagram WD 2M, see page 175

Subject to technical alterations and amendments.

English

Summary of Contents for WD 1M

Page 8: ...WD 2 ...

Page 9: ...WD 2M ...

Page 179: ...170 Setback function ...

Page 180: ...171 USB interface ...

Page 181: ...172 Exploded Drawing WD 2 WD 2 ...

Page 182: ...173 Circuit Diagram WD 2 ...

Page 183: ...174 Exploded Drawing WD 2M WD 2M ...

Page 184: ...175 Circuit Diagram WD 2M ...