BDA UP 14 Z – 03/15 – REV. 0

Page 35 / 71

4.5 Release

Button

In case of jammed jaws caused by operation

or handling errors or wrongly placed

terminals the jaws can be opened as follows:

+

Press Release Button.

5

Transport and Installation

5.1 Transport

The weight of the pneumatic Crimp Machine UP 14 Z is approx. 13 kg.

CAUTION

+

During transport and installation of the machine wear suitable safety shoes.

ATTENTION

+

Tubes must not be damaged.

5.2 Installation

ATTENTION

+

Position the pneumatic Crimp Machine UP 14 Z on a flat surface and assure the stability of

the machine. Ensure that the table or bench is stable enough to support the machine in

normal use.

+

Assure an appropriate table height. The table height is depending on the position of the

operator, (work in sitting or standing position) according to prEN 894-4:2004, Table A.1.

+

Assure an appropriate illumination of the working place. (EN 1837:1999 – chapter 4.2: “The

general value of illumination has to be 500 lx [...]").

INFORMATION

+

To reduce production noise or vibration, the machine can be placed on an insulating rubber

mat.

Place the foot pedal on the floor. No other place is allowed!

Fig. 4.4

Summary of Contents for UP 14 Z

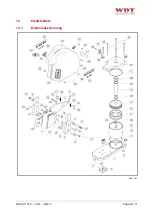

Page 22: ...BDA UP 14 Z 03 15 REV 0 Page 22 71 14 Ersatzteilliste 14 1 Explosionszeichnung Abb 14 1...

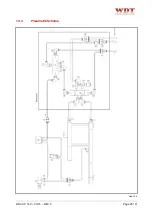

Page 25: ...BDA UP 14 Z 03 15 REV 0 Page 25 71 14 3 Pneumatik Schema Abb 14 2...

Page 47: ...BDA UP 14 Z 03 15 REV 0 Page 47 71 14 3 Pneumatic Diagram Fig 14 2...

Page 70: ...BDA UP 14 Z 03 15 REV 0 Page 70 71 14 3 Sch ma pneumatique Fig 14 2...