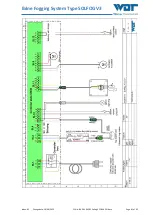

Brine Fogging System Type SOLFOG V3

Index: 02

Change date: 19/09/2023

OI No.: BA DW 042-02 Solfog V3 CB36 EN.docx

Page 50 of 65

9

Maintenance / Fault removal

9.1

Open/close the control housing

During fault removal, it may be necessary to open the control housing.

WARNING!

Danger of electric shock!

Dangerous electrical voltage!

All work on the device must be carried out by specialist personnel only!

All electrical installations and any work on the device’s electrical components

must be carried out by authorised electricians only!

Prior to starting work, disconnect the devices from the power supply and se-

cure them against being reactivated!

After corresponding electrical installation or repair, test all protective

measures used (e.g., earthing resistance)!

ATTENTION!

Danger due to static charge!

This safety notice denotes electronic components that may be damaged by electro-

static discharges.

The generally accepted safety precautions for ESD-sensitive devices must be ob-

served when handling the devices!

In particular, the following applies for work on the control board:

Only unplug or plug in connectors when they are disconnected from the

power supply!

As the person handling the device, please discharge yourself electrostatically

for at least 5 seconds prior to directly touching the devices, e.g., by touching a

grounded part of the system or by wearing an ESD antistatic wrist strap con-

nected to ground!

Fig. 65: Open control housing

1)

Unlock the locking knob (Fig. 65,

No. 23) with a screwdriver.

2)

Press down on both recessed grips

(Fig. 65, No. 24) until the housing

snaps open.

3)

Rotate the cover to the side.

Close the housing in reverse se-

quence.

02

24

23

24