7

www.waynepumps.com

CWS Series

INSTALLATION (CONTINUED)

5. Slope the horizontal pipes upward toward the pump to prevent

trapping air. If horizontal distance exceeds 25 feet, see Chart 1 for

recommended pipe sizes.

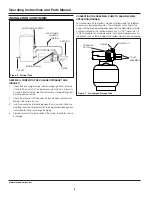

DRILLED WELL (2 IN.) WITH SINGLE PIPE PACKER (FIGURES 16

AND 4)

NOTE:

Single pipe packer jets rely on the space between single pipe and

inside of well casing for return water to operate jet. Two inch installations

must use 1-1/4 in. galvanized steel pipe with special turned couplings (1-

13/16 in. O.D.) to avoid restricting flow of return water back to jet.

1. Assemble the foot valve and packer to the jet body.

2. Lubricate the rubber cups with petroleum jelly.

3. Attach the first section of pipe and lower jet into well.

4. Add pipe until the jet is positioned 5 - 15 feet below the lowest

anticipated water level. The jet should never be closer than 5 feet

from the bottom of the well or sand and sediment may be drawn

into the system.

5. With the jet in position, fill the pipes with water to make sure the

rubber cups are sealed against inside of the well casing. It may be

necessary to move the jet up and down to seat the cups.

6. Install the casing adapter and the horizontal pipes.

7. Slope both pipes upward toward the pump to eliminate trapping air.

If the horizontal distance exceeds 25 feet, see Chart 1 below, for the

recommended pipe sizes.

CHART 1 - PIPE SIZING

Pump Model

Pump

Opening

Horizontal Distance

(Feet)

0-25

26-100

Deep Well

Inlet: Suction

1-1/4 in.

1-1/2 in.

Inlet: Drive

1 in.

1-1/4 in.

Outlet

3/4 in.

1 in.

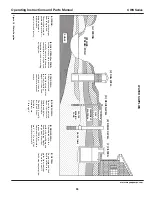

DEEP WELL PUMP WITH HORIZONTAL AND VERTICAL

STORAGE TANK (FIGURES 5 AND 6)

1. Install the air volume control on the tank as shown.

1-1/4 IN. PIPE

Figure 4 - Single Pipe Jet (2” Casing)

PACKER

FOOT VALVE

CUPS

2. Connect the copper tube from the air volume control to the 1/8 in.

NPT opening directly above the 1-1/4 in. opening on the front of the

pump.

3. Install a valve and isolating hose between the system and the house

plumbing to aid in pump removal for servicing and for reducing noise

transmitted through the house piping.

4. Provide a faucet at the lowest point in the system to drain for service

or storage.

Figure 5 - Horizontal Tank

AIR

VOLUME

CONTROL

TUBING

OUTLET

AIR

VOLUME

CONTROL

PRESSURE SWITCH

PRIME PLUG

TO JET

ASSEMBLY

CONVENTIONAL TANK

PUMP