10

www.waynepumps.com

Operating Instructions and Parts Manual

OPERATION (CONTINUED)

L2

3

L1

1

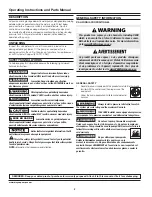

Figure 9 - Electrical Connections

MOTOR

LINE

GROUND

SCREW

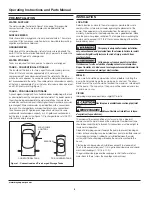

Figure 10 - Voltage Selector

230 V

115 V

4. Open a faucet to vent the system.

5. Start the motor. Water will pump in a few minutes. If pump fails to

prime in 5 minutes, stop motor and refill pump with water. Priming

time is proportional to the amount of air in inlet pipe. Do not allow

pump to get hot.

6. Let the system operate for several minutes to flush all pipes.

7. Close faucet and allow pump to build pressure in tank. When the

pressure reaches the cut-out setting, the motor will stop.

The system is now in operation and will automatically cycle on demand.

PRIMING THE DEEP WELL PUMP

To prevent damage to the pump, do not start

motor until pump has been filled with water.

Pour éviter d’endommager la pompe, ne pas

démarrer le moteur tant que la pompe n’a pas été remplie d’eau.

1. Remove prime plug.

2. Fill pump and piping completely full of water.

3. Replace the prime plug.

4. Close the control valve (Figure 11) and open a nearby faucet.

5. Start the motor. The pressure inside the pump body will build almost

immediately as the pump, jet and piping become completely filled

with water.

6. Slowly open the control valve. Water will begin to flow. Continue to

open the control valve until maximum flow is achieved. Opening the

valve too far will cause the water to stop flowing.

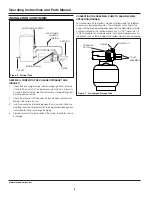

Figure 11 - Control Valve

OPEN

1/4 IN. TURN

CLOSED

7. Adjust the valve until there is a steady flow of water. The valve should

be opened as much as possible without losing pressure.

8. Let the system operate for several minutes to flush all piping.

9. Close the faucets and allow the pump to build pressure in the tank.

When the pressure reaches the cut-out setting, the motor will stop.

The system is now in operation and will automatically cycle upon

demand.