please do not return this product to the store.

Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at

1-888-827-3667

for Consumer Assistance or online at

www.wayne-dalton.com

23

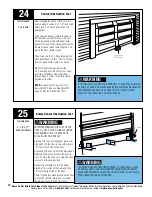

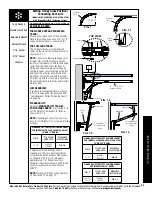

deterMIne the wayne-dalton track

radIus BeIng used:

For Mount hope and pensacola

track:

Measure the curved ends of the horizontal

track to determine if you have a 12” or 15”

radius horizontal track, as shown in FIG. 1.

For portland track:

The horizontal tracks are stamped with

radius on the side of the horizontal track, as

shown in FIG. 1.1.

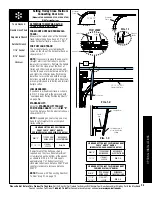

note:

If necessary, remove the upper arm

(straight arm) from the trolley, to use the

lower arm (curved arm). Remove the hairpin

cotter from the clevis pin at the front of

trolley and slide clevis pin out far enough

to slide the upper arm out between the left

and right side of trolley body. Position the

lower door arm so the end with the single

hole lines up with the clevis pin. Slide clevis

pin completely back into trolley and reinstall

hairpin cotter.

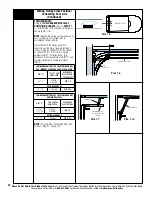

low headrooM:

If you have low headroom track, as shown

in FIG. 1.6 on page 24, then proceed with

“Low Headroom Trolley Positioning Charts”

on page 24.

standard lIFt:

using the

standard lIFt trolley

posItIonIng charts

, refer to DIM “x” to

set the distance from header to trolley, as

shown in FIG. 1.2.

note:

Depending on your setup, you may

have to cut straight arm to accomplish trolley

settings.

If adjustment of the trolley position is

required, use the close travel adjustment

screw located on the bottom of the opener,

as shown in FIG 1.5. A 1/4 turn equals

approximately 1” of trolley travel; turn

clockwise to decrease distance DIM “x” and

counter-clockwise to increase distance

DIM “x”.

note:

Proceed with “Connecting Door Arm

To Door” Step 21, on page 15.

standard lIFt trolley posItIonIng chart

For (Model 9700) 15” radIus

DIM “x”

TYPE OF ARM

BEINg USED

REFERENCE

IllUSTRATIONS

10 9/16”-

14 5/8”

STRAIGHT /

CuRVED

FIg. 1.3

I

setting trolley close position/

connecting door arm

(Models 9100, 9400, 9600, 5120, 5140 & 9700)

with torqueMaster® or extension springs

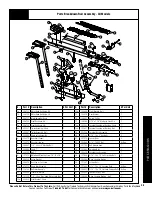

FIG. 1.3

Cut Straight Arm To

Accomplish Trolley

Setting

Curved

Arm

Straight Arm

FIG. 1.4

Straight Arm

Curved Arm

Cut Straight Arm To

Accomplish Trolley

Setting

12”

Stamped

Radius

12”

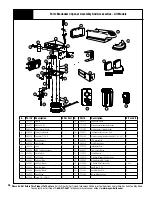

FIG. 1.1

Horizontal

Track

FIG. 1

Horizontal

Track

12” OR 15”

standard lIFt trolley posItIonIng chart

For (Models 9100, 9400, 9600, 5120 & 5140)

10” and 12” radIus

DIM “x”

TYPE OF ARM

BEINg USED

REFERENCE

IllUSTRATIONS

11 1/2”

CuRVED /

STRAIGHT

FIg. 1.4

standard lIFt trolley posItIonIng chart

For (Models 9100, 9400, 9600, 5120 & 5140)

14” and 15” radIus

DIM “x”

TYPE OF ARM

BEINg USED

REFERENCE

IllUSTRATIONS

13”-15”

CuRVED /

STRAIGHT

FIg. 1.4

FIG. 1.2

Top Section

10”, 12”, 14”, OR 15”

Standard Lift Track

“x”

Clevis Pin

Hairpin Cotter

Trolley

TOP vIEw

Tools Needed:

Needle Nose Pliers

Adjustable Wrench

Ratchet Wrench

7/16” Socket

9/16” Socket

hacksaw

OPTIONAL

INST

ALLA

TION

S