6 PWF Filter Systems

WARNING

!

Do not exceed water pressure of 120 psi (8.2 bar). Do not

exceed 110°F (43.3°C). Do not subject unit to freezing

conditions.

General Installation Instructions

1. Turn off water heater(s).

2. Turn off the main water supply to the home and open an inside

faucet (cold and hot) to relieve any pressure within the plumbing

system.

Select Location

1. Place the system in the desired installation location. Make sure

that the location is level and sturdy enough to support the weight

of the system once it is in operation.

2. You will need to locate the filter system at least 10 feet away

from the hot water heater so that hot water does not backup

and damage the filter system.

3. You will need a drain close by for disposal of regenerated waste-

water.

4. If installing the filter system in an outside locations, make sure to

protect softener from the elements, such as freezing tempera-

tures, rain, sunlight and contamination

System Components Described

15

SYSTEM COMPONENTS DESCRIBED

SERVICE INSTRUCTIONS

DRIVE ASSEMBLY

Remove the valve cover to access the drive assembly.

Disconnect the power source plug (black wire) from the PC

board prior to disconnecting the motor or water meter plugs

from the PC board. The motor plug connects to the two-pin

jack on the left-hand side of the PC board. The power source

plug connects to the four-pin jack. The four-pin jack is

between the two-pin and three-pin jacks. The water meter

plug (gray wire) connects to the three.

The PC board can be removed separately from the drive brack-

et but it is not recommended. Do not attempt to remove the dis-

play panel from the PC board. Handle the board by the edges.

To remove the PC board from the drive bracket, unplug the

power, water meter and motor plugs from the PC board. Lift the

middle latch along the top of the drive bracket while pulling out-

ward on the top of the PC board. The drive bracket has two

plastic pins that fit into the holes on the lower edge of the PC

board. Once the PC board is tilted about 45˚ from the drive

bracket it can be lifted off of these pins. To reinstall the PC

board, position the lower edge of the PC board so that the

holes in the PC board line up with the plastic pins. Push the top

of the PC board towards the valve until it snaps under the

middle latch, weave the power and water meter wires into the

holders and reconnect the motor water meter and power plugs.

The drive bracket must be removed to access the drive cap

assembly and pistons or the drive gear cover. It is not

necessary to remove the PC board from the drive bracket to

remove the drive bracket. To remove the drive bracket start by

removing the plugs for the power source and the water meter.

Unweave the wires from the side holders. Two tabs on the

top of the drive back plate hold the drive bracket in place.

Simultaneously lift the two tabs and gently ease the top of

the drive bracket towards your body. The lower edge of

the drive bracket has two notches that rest on the drive

back plate. Lift up and outward on the drive bracket to

disengage the notches.

To reassemble seat the bottom of the drive bracket so the

notches are engaged at the bottom of the drive back plate.

Push the top of the drive bracket towards the two latches. The

drive bracket may have to be lifted slightly to let the threaded

piston rod pass through the hole in the drive bracket. Maintain

a slight engaging force on top of the drive bracket while

deflecting the bracket slightly to the left by pressing on the

side of the upper right corner. This helps the drive gears

mesh with the drive cap assembly. The drive bracket is

properly seated when it snaps under the latches on the drive

back plate. If resistance is felt before latching, then notches

are not fully engaged, the piston rod is not in hole, the wires

are jammed between the drive bracket and drive back plate,

or the gear is not engaging the drive cap assembly.

To inspect drive gears, the drive gear cover needs to be

removed. The drive gear cover is held in place on the drive

bracket by three clips. The largest of the three clips is always

orientated to the bottom of the drive bracket. Before trying to

remove the drive gear cover, the drive bracket must be

removed from the drive back plate. The drive gear cover can

be removed from the drive bracket without removing the

motor or the PC board. Simultaneously, push in and down on

the large clip at the bottom and the clip on the left-hand side

of the drive bracket behind the PC board. Keep your other

fingers behind the drive gear cover so the drive gears do not

drop on the ground. Replace broken or damaged drive gears.

Do not lubricate any of the gears. Avoid getting any foreign

matter on the reflective coating because dirt or oils may inter-

fere with pulse counting.

The drive gear cover only fits on one way, with the large clip

orientated towards the bottom. If all three clips are outside of

the gear shroud on the drive bracket the drive gear cover slips

easily into place.

The drive bracket does not need to be removed from the drive

plate if the motor needs to be removed. To remove the motor,

disconnect the power and motor plugs from the jacks on the PC

Service Instructions

Figure 17:

Figure 18:

Figure 19

Figure 20::

NOTICE

NOTICE

NOTICE

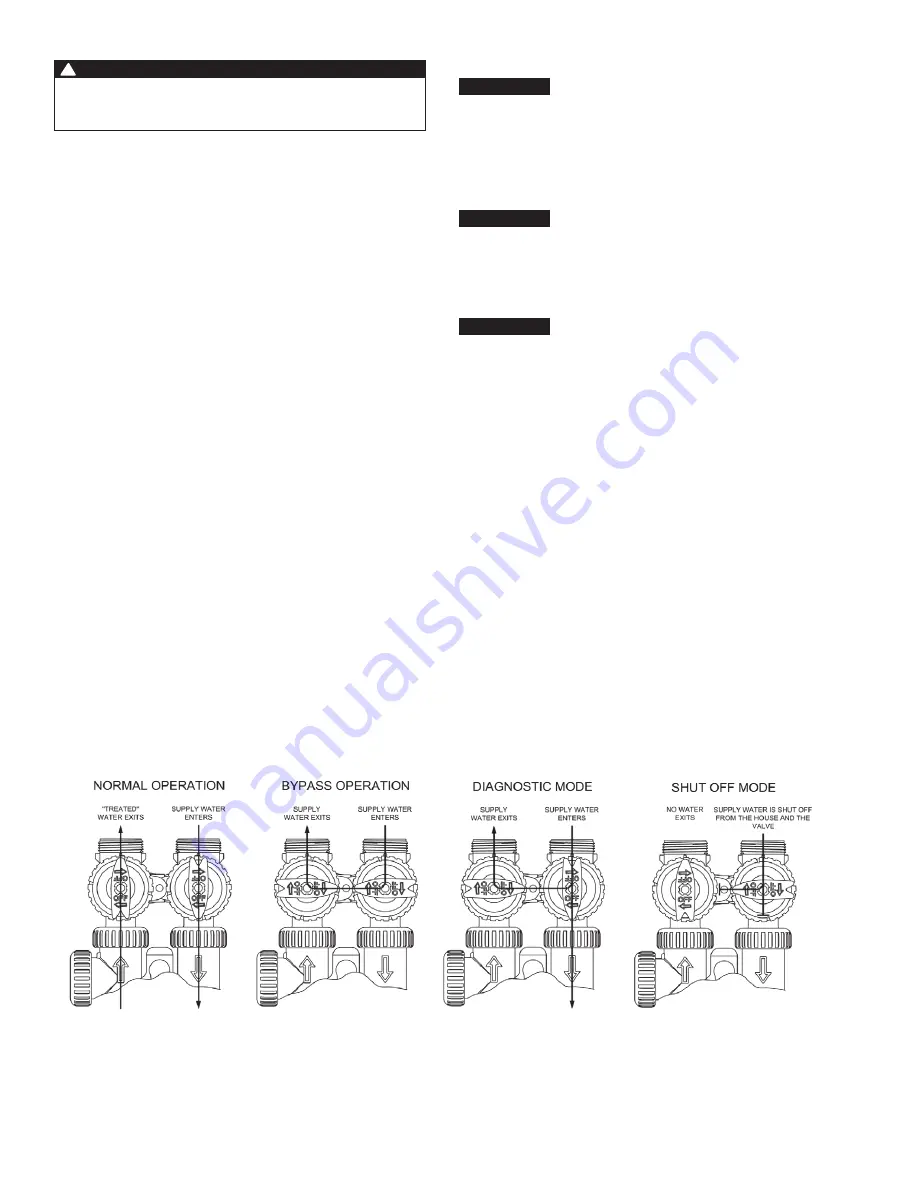

Install a By-Pass

Always install a bypass, either a 3-way valve system or the standard

bypass for the valve you have. This will allow you to shut off the

water supply to the softener, but still have water in the house if the

softener is in need of repair.

After a location has been determine install bypass onto the control

valve. (On page 7, Figures 1 and 3 show standard bypass on valve.)

(Figures 2 and 4 show 3-way by pass plumbing.)

If installing a 3-way bypass valve, do so now.

Close main water supply valve, at the well or at the water meter.

Shut off electrical or fuel supply to the water heater.

Open all faucets to drain pipes.

The bypass (provided) easily connects to the valve body using nuts

that only require hand tightening. The split ring retainer design holds

the nut on and allows load to be spread over the entire nut surface

area reducing the chance for leakage.

Make certain the nut is placed on first, then the split retainer ring, fol-

lowed by the o-ring to make the seal. A silicon lubricant may be used

on the black o-ring seals. This design allows for an approximate

2-degree misalignment of the plumbing. This design will allow for

minor plumbing misalignments, but should never handle the weight

of the plumbing system.

Once by-pass installed, place the by-pass valve in the by-pass posi-

tion