8

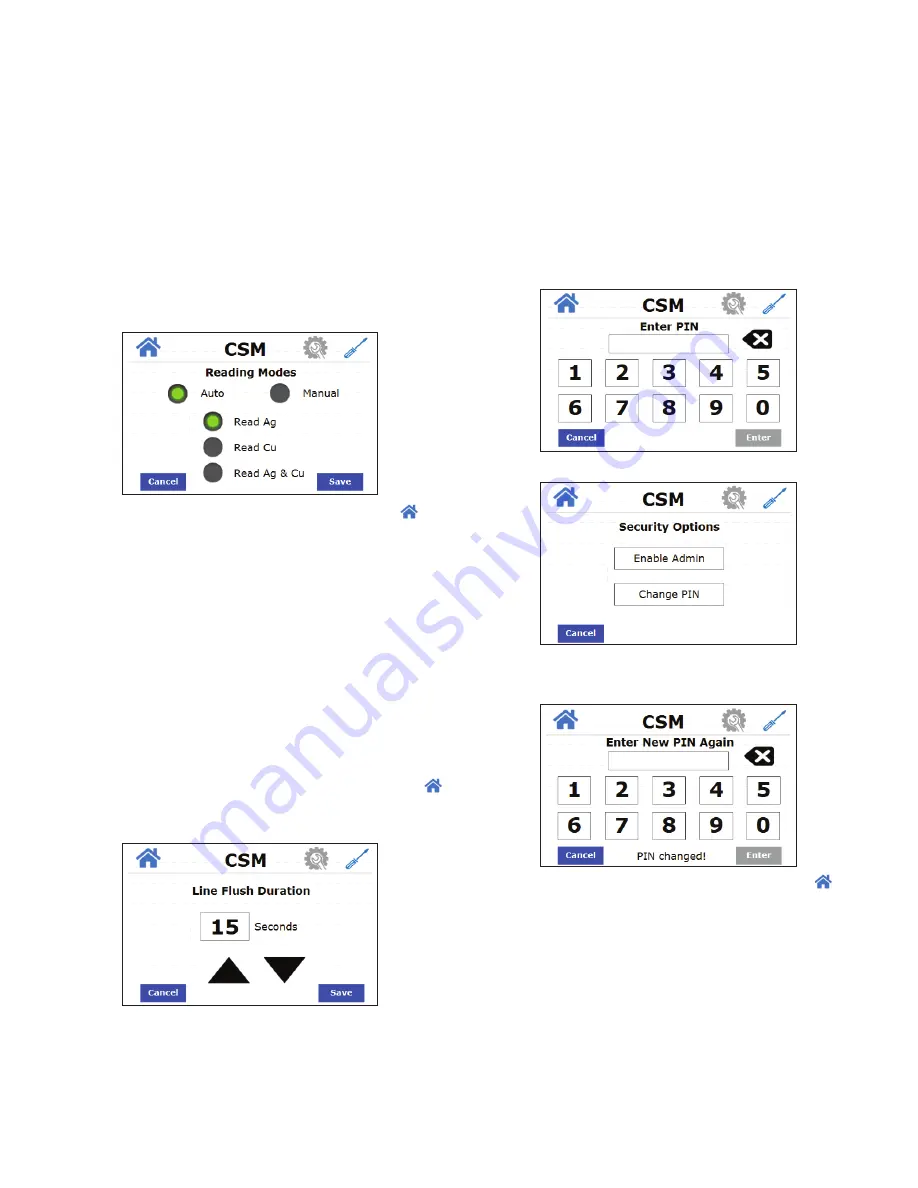

5.6 Setting the Reading Mode

The CSM has 2 different modes of taking readings, The first is Auto

Mode. In Auto Mode, measurements are taken at a preset time interval

and displayed on the Home screen. A countdown clock showing the

time until the next reading is displayed in the status bar on the bottom

of the home screen.

The second mode is Manual Mode. In Manual Mode, the date/time

button on the home screen is used to take an on-demand reading. The

date/time button displays the date and time of the last reading while

the measurement data is shown to the right. The status bar shows

GOOD, rather than a countdown clock.

To set the Reading Mode:

1. Press

Measure Ag, Cu, Ag/Cu

on the Configuration Menu screen.

2. Press

Auto

or

Manual

.

3. Press which parameter you wish to monitor: Silver, Copper or both.

Then press

Save

.

4. Once the desired Reading Mode has been saved, press the

button to return to the home screen or press

Cancel

to return to the

previous menu.

5.7 Adjusting the Line Flush Duration

A line flush is necessary to wash the cuvette between measurements.

The line flush setting is used to set the amount of time in seconds to

wash the cuvette. This time will be applied to the wash step in the

reading sequence, discussed later in this manual. The default duration

is 5 seconds, which is also the minimum. The maximum line flush

duration is 60 seconds. The suggested line flush duration is 1 second

for every foot of sample line tubing (assuming inlet pressure of 4-60psi)

To adjust the line flush duration:

1. Press

Line Flush Setting

on the Configuration Menu screen.

2. Using the up and down arrows, set the desired duration for the line

flush in seconds.

3. Once the desired Line Flush Duration has been saved, press the

button to return to the home screen or press

Cancel

to return to the

previous menu.

5.8 Security Setting

The CSM has a security setting that when enabled will only allow

authorized users with a valid numeric password to configure the

instrument. The user must enter a 6 digit PIN to gain admin access.

There is a Master PIN that is hard-coded into the software and it

cannot be changed. If a user forgets their personal pin, HF can provide

the Master PIN and the instrument will prompt the user to choose a

new PIN. Contact HF scientific Technical Service Department for the

Master PIN.

To enable a Security PIN:

1. Press

Security

on the Configuration Menu screen.

2. If this is the first time entering the Security PIN, enter the Master

PIN provided by HF scientific. If you already have a personal PIN

assigned, enter that PIN. Press

ENTER

.

3. Press Enable Admin or Change PIN.

4. If selecting to

Enable Admin

, enter the security PIN again to

enable. If selecting

Change PIN

, enter the new pin. You will be

prompted to enter the new pin a second time. Then press

Enter

.

5. Once the security PIN or setting has been saved, press the

button to return to the home screen or press

Cancel

to return to the

previous menu.