5

Wanner Engineering, Inc.

United States

Instant Information: www.wannereng.com

(61) 33-5681 Fax (61) 33-6937

SCK-991-400B

Operation

Preparation For Operation

Caution: the following preparation must be done before the

pump is operated for the first time. Failure to follow these

instructions will result in serious damage to the pump.

Initial Lubrication

Note:

Oilers are set at the factory to their lowest position. This

setting places the oil level just below the center of the bottom

ball of the bearing when the housing is level. Higher levels may

cause churning and overheating of the bearings; lower levels

may not provide enough lubrication and may promote rapid

wear.

The correct oil level will be visible at the center of the

sign oil gauge.

Standard pumps are shipped with empty oil reservoirs.

Oil must

be added before operating the pump.

Attach the oiler to the

bearing housing, fill the bottle with oil, and place it in position.

Continue filling the bottle until it remains full of oil. Do not add

oil to the reservoir except through the oiler bottle.

Use a good grade of SAE 10W30 oil.

Keep the air vent clean to prevent pressure buildup caused by

normal heating that occurs in operation. A Trico Optomatic Oiler

No. EB-64 with a 4-oz capacity bottle is used.

The correct bottle

must be used with the corresponding oiler body.

Mechanical Seals

When mechanical seals are furnished with the pump, the

description and identification are indicated on the order writeups,

which are a part of the order acknowledgment, dimension print,

and packing list. The seals are installed and adjusted at the

factory. To properly prepare the seal for operation, various cooling

and flushing flows may have to be connected. Liquid from an

outside source may be required. Connect necessary cooling

and flushing flows to the seal, and be sure it is turned on before

starting the pump.

Important Precautions

Check the following items before starting the pump:

• Pump rotates freely by hand

Important: The motor rotation must be checked before

connecting the shaft coupling. Incorrect pump rotation

for even a short time will dislodge the impeller and

damage the impeller or casing, or both. The pump shaft

must turn clockwise when viewed from the motor end.

• Coupling is aligned

• Oiler is full and oil level is correct

• Suction valve is fully open

• Pump and suction line are full of fluid

• Water is supplied to stuffing box or gland flush

Priming

Vent all air from the suction line, and fill the line with liquid. Start

the pump with the discharge valve cracked open. After the

discharge pressure stabilizes, gradually open the discharge valve

to the required position. If flow is lost, close the discharge valve

and wait a few seconds for the discharge pressure to rebuild.

Continued flowing difficulty indicates an improper selection or

installation. Running the pump too long with improper prime

may destroy the sealing faces of the mechanical seal. It may

also cause mechanical damage from pulsation and interference

between rotating and stationary components.

Thermal shock may crack the ceramic stationary seat if the

temperature is raised from room temperature to 250°F in less

than 30 seconds.

Maximum Operating Conditions

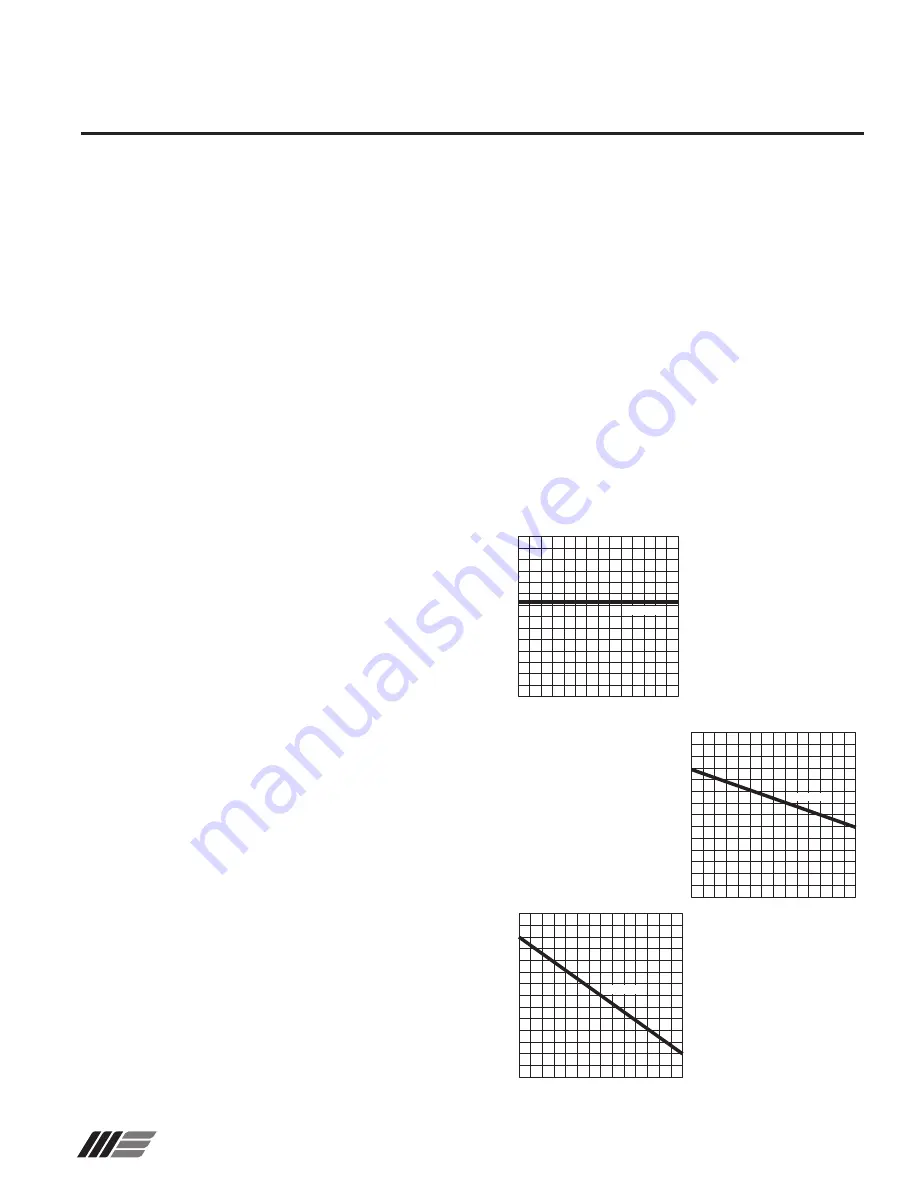

Note: These maximum operating conditions apply to pumps which

are exposed to room temperatures without external insulation.

Maximum operating temperature and pressure conditions are

shown in Fig. 5 below.

Notes:

• Maximum service temperature for all Kynar pumps: 250°F.

• For insulated pumps, multiply “Maximum Discharge Pressure”

by 0.8.

• Higher maximum discharge pressures are allowed for A50,

A60, or A70 pumps when pipe stress is removed from the

discharge flange. Contact the factory for details.

Temperature (F)

80

90

100

110

120

130

140

150

Maximum Discharge Pressure (PSI)

75

100 125 150 175 200 225 250

KYNAR 370

W0445

Temperature (F)

145

150

155

160

165

170

175

180

Maximum Discharge Pressure (PSI)

75

100 125 150 175 200 225 250

KYNAR 370

W0446

Temperature (F)

80

90

100

110

120

130

140

150

Maximum Discharge Pressure (PSI)

75

100 125 150 175 200 225 250

KYNAR 370

W0444

Fig. 5A:

Pump Size AA, AB

without insulation on

atmospheric side

Fig. 5B:

Pump Size A30, A40

without insulation on

atmospheric side

Fig. 5C:

Pump Size A50, A60,

A70 without insulation

on atmospheric side