42

If the hotplate is not hot enough, the ash door can be opened as an

exception.

If the heat

capacity of the domestic water boiler is exceeded then the excess energy is let off through

the heat sink (closed circuit).

This must not be allowed to be a regular situation.

1.7 Roasting and baking

Roasting and baking in winter

- Grate position "DOWN"

- central control to "III"

- secondary air slide "OPEN"

(only K148)

Close the top lids, if possible. A lively fire is necessary

to roast

. Wood is particularly suit-

able, to keep the oven temperature over 200 °C. The roasting oven temperature can be

controlled by adding fuel and by using the temperature control.

A weak fire is sufficient

for baking.

Turn the temperature control down and only add a little

fuel. The baking oven should in any case be preheated and do not use tinplate tins.

Roasting and baking in summer

-

Grate in position "UP"

- central control to "III"

- secondary air slide "CLOSED"

(only K148)

Otherwise the same instructions as above.

If the roasting oven temperatures goes over 300 °C, turn the temperature control

back and open the roasting oven door on the catch.

Oven lining

Place tinned or round shaped cakes on the roasting rack on the bottom shelf. To quick

roast use the top shelf.

1.8 Care and cleaning

The period of time between cleaning the stove and the flue pipes depends largely on the

type of fuel used, the draught and the mode of operation. It should certainly be cleaned if:

-

heating performance drops,

-

the fuel burns poorly despite powerful air intake (open ash door)

-

smoke occasionally comes out of the doors or there is a smell of flue gas in the room)

or

-

the time for heating is excessive.

-

Unnecessary escape of dust can be avoided if all opening on the stove remain closed,

if they are

not

actually being used for accesses at the time.

-

Take the hotplate out (Fig. 15) and clean out the chimney connection (Fig. 16). The

hotplate can remain in place while cleaning for the upper smoke connection areas.

-

sweep soot and ashes from the oven roof into the draught shafts

Summary of Contents for K148

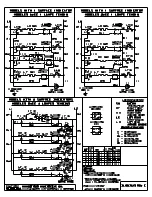

Page 4: ...4 Ger teaufbau K148F K148...

Page 26: ...26 Bild 10 Bild 11 Bild 12 Bild 15 Bild 13 Bild 14 Bild 16 Bild 17 Bild 18...

Page 27: ...27 Bild 20 Bild 21 Bild 22 Bild 23 Bild 24 Bild 25 Bild 27 Bild 26 Bild 28...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 36: ...36 Assembly K148F K148...

Page 57: ...57 Fig 10 Fig 11 Fig 12 Fig 15 Fig 13 Fig 14 Fig 16 Fig 17 Fig 18...

Page 58: ...58 Fig 20 Fig 21 Fig 22 Fig 23 Fig 24 Fig 25 Fig 27 Fig 26 Fig 28...

Page 59: ...____________________________________________________________ 59 Fig 31 Fig 30 Fig 29...

Page 64: ...64 Structure de l appareil K148F K148...

Page 84: ...84 Image 10 Image 11 Image 12 Image 15 Image 13 Image 14 Image 16 Image 17 Image 18...

Page 85: ...85 Image 20 Image 21 Image 22 Image 23 Image 24 Image 25 Image 27 Image 26 Image 28...

Page 86: ...____________________________________________________________ 86 Image 31 Image 30 Image 29...

Page 92: ...92 Struttura dell apparecchio K148F K148...

Page 115: ...115 Fig 10 Fig 11 Fig 12 Fig 15 Fig 13 Fig 14 Fig 16 Fig 17 Fig 18...

Page 116: ...116 Fig 20 Fig 21 Fig 22 Fig 23 Fig 24 Fig 25 Fig 27 Fig 26 Fig 28...

Page 117: ...____________________________________________________________ 117 Fig 31 Fig 30 Fig 29...