2787-2154

Operation

34

Product manual | Version: 1.0.2

Power Supply Pro 2

8

Operation

8.1 Operation via Buttons

Using the

+

und

−

buttons on the front of the product, you can make the following set-

tings:

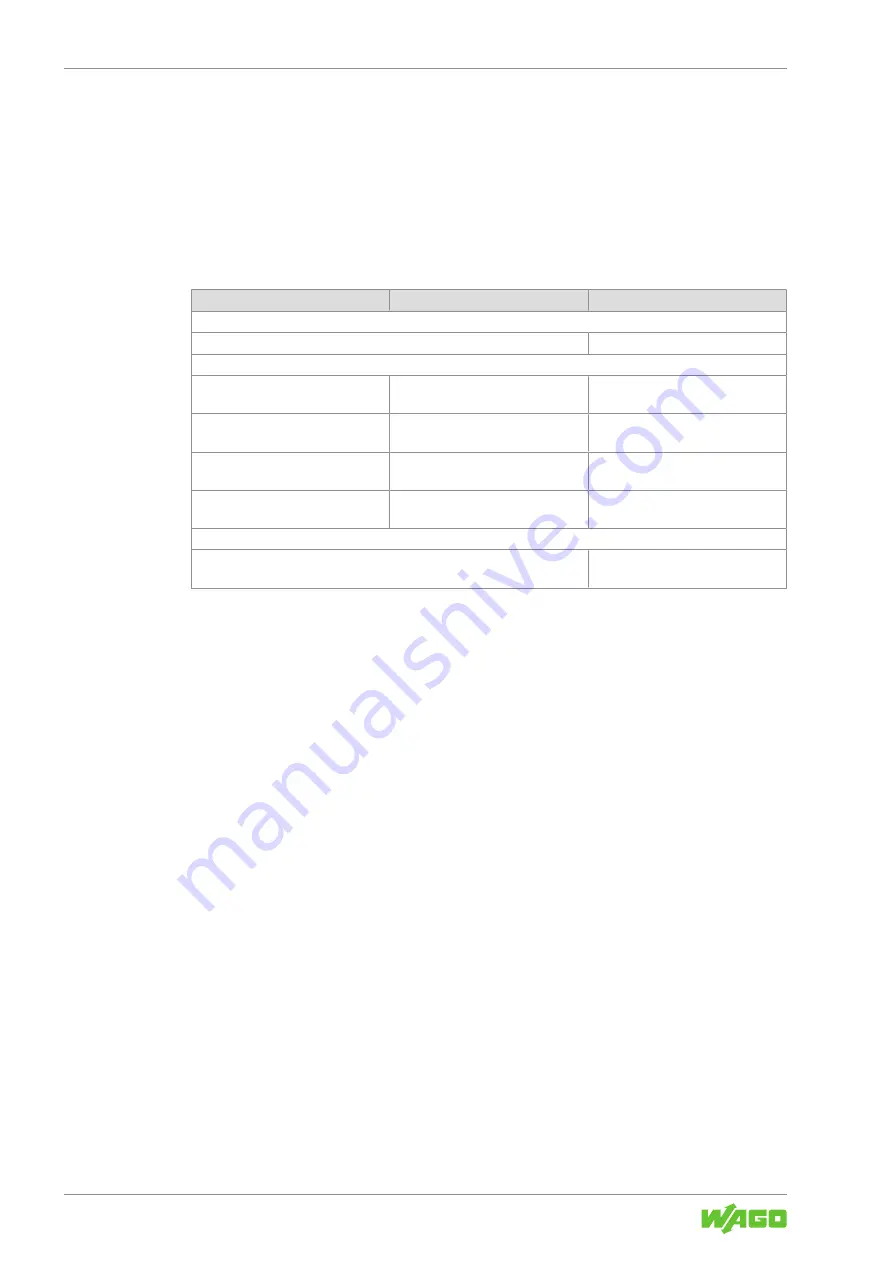

Table 41: Operation via Buttons

Button [+]

Button [−]

Function

Switch product on or off

Hold down simultaneously for 3 seconds

The product is switched on or off.

Set output voltage

Press once

-

The output voltage increases in

steps.

Press and hold

-

The output voltage increases con-

tinuously.

-

Press once

The output voltage is reduced in

steps.

-

Press and hold

The output voltage is reduced con-

tinuously.

Reset product to factory settings

Hold down simultaneously for 10 seconds

The product is reset to the factory

settings.

During ongoing operation, you can set the output voltage and reset the product to the fac-

tory settings. These settings can be saved and then remain available when the product is

switched off and back on.