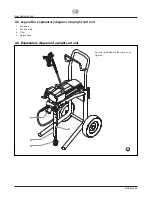

Unit on low carriage

2.

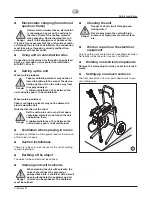

General view of application

2.1

Application

All painting jobs in the workshop and on the building

site, small dispersion work with the spray gun or inter-

nally fed Airless roller.

Examples of objects of spraying

Doors, door frames, balustrades, furniture, wooden

cladding, fences radiators (heating) and steel parts, inter-

nal ceilings and walls.

2.2

Coating materials

Processible coating materials

Dilutable lacquers and paints or those containing sol-

vents, two-component coating materials, dispersions, la-

tex paints.

No other materials should be used for spraying without

WAGNER’s approval.

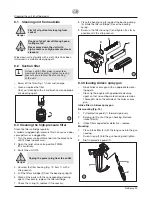

Filtering

Despite suction filter and insertion filter in the spray gun,

filtering of the coating material is generally advisable.

Stir coating material before commencement of work.

Attention:

Make sure, when stirring up with

motor-driven agitators that no air bubbles

are stirred in. Air bubbles disturb when

spraying and can, in fact, lead to interruption

of operation.

i

Pay attention to the Airless quality of the

coating materials to be processed.

i

Viscosity

With this unit it is possible to process highly viscous

coating materials of up to around 20.000 MPa·s.

If highly viscous coating materials cannot be taken in by

suction, they must be diluted in accordance with the

manufacturer’s instructions.

Two-component coating material

The appropriate processing time must be adhered to ex-

actly. Within this time rinse through and clean the unit

meticulously with the appropriate cleaning materials.

Coating materials with sharp-edged additional

materials

These have a strong wear and tear effect on valves,

high-pressure hose, spray gun and tip. The durability of

these parts cane be reduced appreciably through this.

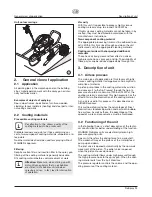

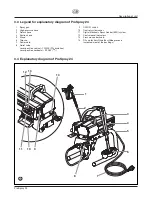

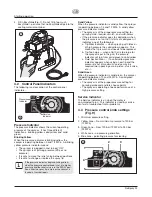

3. Description of unit

3.1

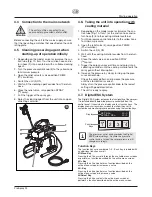

Airless process

The main areas of application are thick layers of highly

viscous coating material for large areas and a high con-

sumption of material.

A piston pump takes in the coating material by suction

and conveys it to the tip. Pressed through the tip at a

pressure of up to a maximum of 230 bar (23 MPa), the

coating material is atomised. This high pressure has the

effect of micro fine atomisation of the coating material.

As no air is used in this process, it is described as an

AIRLESS process.

This method of spraying has the advantages of finest

atomisation, cloudless operation and a smooth, bubble-

free surface. As well as these, the advantages of the

speed of work and convenience must be mentioned.

3.2

Functioning of the unit

In the following there is a short description of the techni-

cal construction for better understanding of the function.

WAGNER ProSpray units are electrically driven high-

pressure spraying units.

A gear unit transfers the driving force to a crankshaft.

The crankshaft moves the pistons of the material feed

pump up and down.

The inlet valve is opened automatically by the upwards

movement of the piston. The outlet valve is opened

when the piston moves downward.

The coating material flows under high pressure through

the high-pressure hose to the spray gun. When the coat-

ing material exits from the tip it atomizes.

The pressure regulator controls the volume and the oper-

ating pressure of the coating material.

ProSpray 24

g

General view of application

Description of unit