ProSpray 24

g

Service Time Screen

The Service Time screen

allows the user to set a service

time interval (in hours). Below

the set time, the screens shows the current amount of hours on

the sprayer. To select the Service TImer screen, press the #4

key.

The screen will toggle between

the service hours and a screen

that allows the user to change

the service time interval.

When the service time interval is set and met by the run hours,

the display will toggle between the "Main screen" and a

"Service Required" screen at sprayer startup. To stop the

toggling, scroll to the "Service Time" screen and either set a

new service time interval or set the service time to "0".

Pressure Screen

The Pressure screen allows

the user to see the current set

point pressure as well as the

actual working pressure.

To select the Pressure screen,

press the #4 key. This screen

is also the Main Screen.

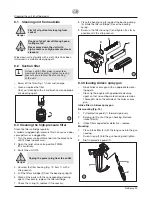

Security Code Screen

The Security Code screen

allows the user to set a four

digit security code to prevent

unauthorized use of the sprayer. If a security code has been

set, the control system display will ask for the code at startup.

If the correct code is entered, the display will show the Main

Screen and the sprayer will operate. If the wrong code is

entered, the display will continue to ask for the correct code

and the sprayer will be disabled. To set or change the security

code, press the #2 key.

Enter the old security code

number to access the screen

that allows the code change. If

the wrong code is entered, the display will continue to ask for

the correct code and the security code cannot be changed.

Enter the new security code.

Once the new code is entered,

the display will automatically

ask that the new code be re-entered for verification. If the same

new code is re-entered, the display will confirm that the new

code has been accepted and return to the Main Screen. If the

new code is re-entered incorrectly, the display will return to the

“Enter New Code Number” screen and the process will repeat.

Prime Screen

The Prime screen appears

when the pressure control knob

is set at the “Min” setting in the

yellow zone.

Clean Screen

The Clean screen appears

when the pressure control knob

is set at the CLEAN position in

the blue zone and the relief valve is in the PRIME position.

CLEAN

PRIME

To inactivate the security function, enter “1111” at

the “Enter New Code Number” screen (this is the

default code that leaves the sprayer unlocked).

As a result, the Main Screen will appear at sprayer

startup.

i

ENTER NEW CODE

NUMBER

ENTER OLD CODE

NUMBER

If the sprayer is new, no security code is set and

the Main Screen will appear at startup. Also,

when setting a security code for the first time, the

“Enter Old Code Number” screen will not appear.

i

SECURITY CODE

SELECT-4

MENU-1

SET MPa

23.0

ACTUAL MPa

22.5

PRESSURE

SELECT-4

MENU-1

SERVICE @ XXXHR

RUN HOURS XX

SERVICE TIME

SELECT-4

MENU-1

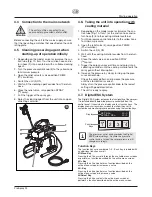

Menu Screens

Several menu screens are available for the user to customize

and monitor sprayer operation. They include Main Screen,

User Pre-Sets, Volume Pumped, Job Volume, Unit Serial #,

TImers, Job Timers, Service Time, Pressure, Security Code,

Prime, and Pulse Clean.

Main Screen

The Main Screen is the default

screen for the control system at

sprayer startup.

Pressing the #2 key switches between PSI

and MPa units of measure.

Press the #1 key to scroll

through the remaining menu screens.

User Pre-Sets Screen

The User Pre-Sets screen

allows the user to set four

different pressure settings and save them for future use. To

select the User Pre-Sets screen, press the #4 key.

Press keys 1 through 4 from

the Select screen to select or

change a pre-set pressure.

Press the #4 key to select the

setting and the Main Screen

will appear.

Press the #2 key to change the

setting. On the following

screen, use the #2/+ key to

increase the setting or the #3/- screen to decrease the setting.

Once the desired setting has been reached, press the #4 key

to set and the Main Screen will appear. To select or change

the remaining three pre-sets, scroll to the User Pre-Sets screen

and repeat the above procedure.

Volume Pumped Screen

The Volume Pumped screen

shows the total number of

gallons or liters sprayed by the

sprayer.

To select the Volume Pumped

screen, press the #4 key.

Job Volume Screen

The Job Volume screen allows

the user to reset a gallon

counter to track usage on

specific jobs.

To select the Job Volume

screen, press the #4 key.

Unit Serial # Screen

The Unit Serial # screen shows

the sprayers serial number.

To select the Unit Serial #

screen, press the #4 key.

Timers Screen

The Timers screen shows the

total time the sprayer has been

turned on as well as the total

time the sprayer has been running (pumping).

To select the Timers screen,

press the #4 key.

Job Timers Screen

The Job Timers screen allows

the user to reset the “ON

TIME” and “RUN TIME” to

track time on specific jobs.

To select the Job TImers

screen, press the #4 key. The

screen will toggle between the

timers and a screen that allows the user to reset the timers.

ON TIME XXXXX:XX

RUN TIME XXXX:XX

JOB TIMERS

SELECT-4

MENU-1

ON TIME XXXXX:XX

RUN TIME XXXX:XX

TIMERS

SELECT-4

MENU-1

SER # XXXXXXXXXX

PRESS 1 FOR MENU

UNIT SERIAL #

SELECT-4

MENU-1

JOB LITERS

XXXX

MENU-1

RESET-3

JOB VOLUME

SELECT-4

MENU-1

LITERS XXXXXX

PRESS 1 FOR MENU

VOLUME PUMPED

SELECT-4

MENU-1

PRE-SET #1

5.2

PRESS +/- TO CHG

MPa SETTING

5.2

SELECT-4

CHG-2

SELECT

PRE-SETS 1-4

USER PRE-SETS

SELECT-4

MENU-1

SET MPa

23.0

ACTUAL MPa

22.5

Starting operation