41

Plast Coat 1030

GB

6.8

BEGINNING OF THE SPRAYING PROCESS

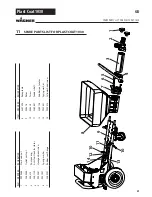

• Open the air flow regulator (fig. 13, 3) and the material tap

(13, 1) at the spray lance.

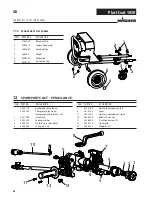

• Adjust the flow of material with the delivery volume con-

troller (fig. 13, 2) on the control unit and set the air quantity

by adjusting the air flow regulator (fig. 13, 3) to attain the

desired spray pattern.

Important: Do not let the mortar spraying

machine run dry. Switch the device off im-

mediately if no more material comes out of

the tip or if the spray line becomes irregu-

lar. Possible reasons for the problem and

how to correct it can be found in the chap-

ter called „Eliminating faults“.

Increased material tap wear. Do not use the

material tap to set the material volume.

The delivery volume controller should be

used for this purpose.

6.9

END OF THE SPRAYING PROCESS

• Close the material tap (Fig. 13, 1).

• Close the air flow regulator (fig. 13, 3).

Always close material tap at end of the

spray process.

COMMISSIONING

햿

1

3

2

POWER

ERROR

SPEED

R

A

F

Summary of Contents for PLASTCOAT 1030

Page 51: ...51 Plast Coat 1030 GB...

Page 79: ...79 Plast Coat 1030 F...

Page 110: ...110 Plast Coat 1030 NL...

Page 111: ...111 Plast Coat 1030 NL...