15

GM 4700AC

OPERATING MANUAL

VERSION 06/2014

ORDER NUMBER DOC2311730

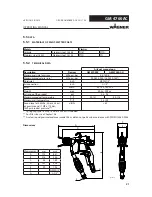

4.2.1

SAFE HANDLING OF WAGNER SPRAY DEVICES

The spray jet is under pressure and can cause dangerous injuries.

Avoid injection of paint or fl ushing agents:

Never point the spray gun at people.

Never reach into the spray jet.

Before all work on the device, in the event of work interruptions and functional faults:

- Switch off the energy/compressed air supply.

- Relieve the pressure from the spray gun and device.

- Secure the spray gun to prevent actuation.

- In the event of functional faults, remedy the fault as described in the "Troubleshooting"

chapter.

If necessary or at least every 12 months, the liquid ejection devices should be checked

for safe working conditions by an expert (e.g., Wagner Service Technician) in accordance

with the guidelines for liquid ejection devices (ZH 1/406 and BGR 500 Part 2 Chapter 2.29

and 2.36).

- If devices have been decommissioned, the examination can be suspended until

the next start-up.

Carry out the work steps as described in the "Pressure Relief" chapter:

- If pressure relief is required.

- If the spraying work is interrupted or stopped.

- Before the device is cleaned on the outside, checked or serviced.

- Before the spray nozzle is installed or cleaned.

In the event of skin injuries caused by paint or fl ushing agents:

Note the paint or fl ushing agent that you have been using.

Consult a doctor immediately.

Avoid risk of injury from recoil forces:

Ensure that you have firm footing when operating the spray gun.

Only hold the spray gun briefl y in a position.

4.2

SAFETY INSTRUCTIONS FOR STAFF

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

Summary of Contents for GM 4700AC

Page 2: ......

Page 55: ...55 GM 4700AC 55 GM 4700AC OPERATING MANUAL VERSION 06 2014 ORDER NUMBER DOC2311730...

Page 79: ......