13

material reduction/projector set cHart / remedy in case of faults

fc9900 Plus

10

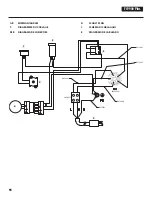

reMedy in caSe of faultS

type of malfunction

A. Restricted air flow or no air flow

B. Filter warning light is on

C. The turbine has no power

D. Excessive arcing/sparking in the

turbine

possible cause

1. Air flow adjustment knob on the spray

gun is turned off

2. Air filters are clogged

1. Air filters are clogged

1. No power at the power supply

2. Circuit breaker has been tripped.

3. Worn turbine brushes

1. Worn turbine brushes

2. Damaged commutator

Measures for eliminating the malfunction

1. Adjust the air flow adjustment knob

2. Clean or replace the filters

1. Clean or replace the filters

1. Check the power supply

2. Reset the breaker. If problem persists, have turbine

inspected at an authorized Wagner service center.

3. Have the brushes replaced at an authorized Wagner

service center

1. Have the brushes replaced at an authorized Wagner

service center

2. Replace the turbine (contact a Wagner service technician)

i

The turbine motor can be damaged if not serviced properly. Have the brushes (P/N 0276878) checked for wear by an

authorized service center every 400 hours.

Clean filters regularly. Clogged filters can cause excessive heat and possibly damage the unit.

For additional troubleshooting information, see the manual that came with your gun.

10.1

Service

Should your spray system need service during the warranty period, return your unit and the proof of purchase to the distributor

where it was purchased. At our option, the unit will be repaired or replaced. In a continued commitment to improve quality, we

reserve the right to make component or design changes when necessary.

9

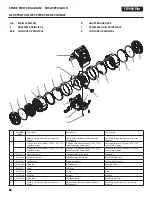

Material reduction/projector Set chart

Before spraying, the material being used must be thinned with an appropriate solvent and the proper projector set must be installed.

It is always best to follow the material manufacturers recommendations and thinning procedures.

There are two simple methods of measuring the proper thickness of a material:

1.

Dip a paint stick into the material and remove it, watching carefully as the material runs off. When the material begins to form

drops, the drops should fall about 1 second apart.

2.

Use a viscosity cup (P/N 0153165). Dip the cup into the material and remove it. Use a watch or clock to time how long the

material drains from the cup in a continuous stream. Once the continuous stream breaks, stop timing and refer to the table

below. Add the appropriate solvent and continue testing until the proper thickness is reached for the type of material you are

using.

Material

viScoSity din-S (4 MM din cup)

projector Set

Solvent-based lacquer paints

15 - 45

3 - 4

Water-soluble lacquer paints

observe manufacturer’s instructions

4 - 5

Wood preservatives (scumble, mordants, etc).

undiluted

2 - 3

Multi-color effect materials, multi-color paint

observe manufacturer’s instructions

6 - 7

Texture and effect paints

observe manufacturer’s instructions

5 - 6