35

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

0

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

105

110

115

120

125

130

135

0

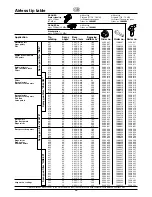

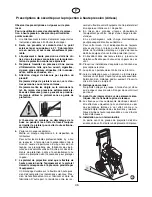

Recoil force N (Newton)*

1.98

1.83

1.57

1.30

1.10

0.91

0.79

0.66

0.53

0.46

This is the force acting on the gun and transmitted to the hand guiding the gun. Values for higher spraying

pressures can be calculated proportionally.

Attention:

An additional turning moment may be caused when using pole guns. Hold pole gun with both hands.

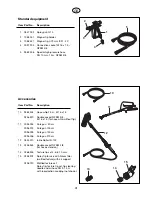

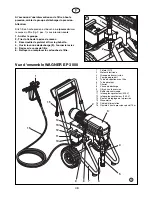

Spray tip selection

Selection of the correct tip is essential for correct and efficient spraying. In many cases, the right tip can be

determined only by conducting a spray test.

Here are a few rules:

The spray fan must be uniform.

If streaks appear in the spray fan, the spraying pressure is too low or the viscosity of the material is too high.

Remedy:

Increase pressure or thin the material. Each pump delivers a specific volume directly proportional to the

size of the tip:

Rule of thumb:

large tip

= low pressure

small tip = high pressure

A very wide range of tips is available with widely ranging spaying angles.

Pressure, bar

Theoretical recoil force diagram for Airless spray tips

Spray tip bore

mm

*Measured with water

GB