2-16

OM D18 us* 1.1 * Sicherheit_25022014.fm

2 Safety

Modifications and spare parts

•

Do not modify the machine and the work equipment/attachment (for

example the safety equipment, lights, tires, straightening and welding work).

•

Modifications must be approved by the manufacturer and performed by

a Wacker Neuson service center.

•

Use only original spare parts.

Protective structures

•

The cabin, rollbar and protective screen are tested protective structures and

may not be modified (for example no drilling, bending, welding).

•

Perform a visual check according to the maintenance plan (for

example check fastenings for damage).

•

If damage or defects are detected, have them immediately checked

and repaired by a Wacker Neuson service center.

•

Have retrofitting work only performed by a Wacker Neuson service center.

•

Replace self-locking fasteners (for example self-locking nuts) by new

ones after removing them.

Summary of Contents for DW100

Page 18: ...1 8 BA D18 us 1 1 D18v100 fm 1 Foreword Notes...

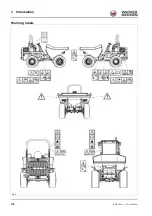

Page 46: ...3 8 BA D18 us 1 1 D18e300 fm 3 Introduction Warning labels Fig 9...

Page 50: ...3 12 BA D18 us 1 1 D18e300 fm 3 Introduction Information labels Fig 20...

Page 54: ...3 16 BA D18 us 1 1 D18e300 fm 3 Introduction ANSI label option Fig 36...

Page 60: ...3 22 BA D18 us 1 1 D18e300 fm 3 Introduction Notes...

Page 144: ...6 10 BA D18 us 1 1 D18t600 fm 6 Transportation Notes...

Page 200: ...8 8 BA D18 us 1 1 D18b800 fm 8 Malfunctions Notes...

Page 216: ...9 16 BA D18 us 1 1 D18t900 fm 9 Technical data 9 15 Dimensions Front skip overview...

Page 218: ...9 18 BA D18 us 1 1 D18t900 fm 9 Technical data Swivel skip with rollbar overview...

Page 220: ...9 20 BA D18 us 1 1 D18t900 fm 9 Technical data Swivel skip with cabin overview...

Page 222: ...9 22 BA D18 us 1 1 D18t900 fm 9 Technical data...

Page 226: ......

Page 227: ......