Disassembly/Assembly Procedures

PD Repair

wc_tx000590gb.fm

34

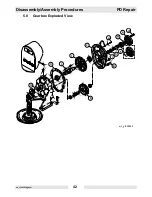

5.4

Replacing the Flapper Valve

See Graphic: wc_gr003452

There are flapper valves located on both the inlet and the outlet sides

of the pump. The procedure for replacing either flapper valve is the

same.

Removal:

5.4.1

Turn off the engine.

5.4.2

Remove the screws (a) and washers that secure the port (b or c) to the

pump water box and remove the port.

5.4.3

Remove the flapper valve (d).

5.4.4

Remove the large and small weights (e and f) from each side of the

flapper valve.

Installation:

5.4.5

Install the weights (e and f) to the flapper valves (d) with screws (g).

CAUTION: Do not over-tighten the screws. Over-tightening will crush

the rubber flapper and may prevent it from sealing properly. Tighten

the screws just so the rubber begins to compress.

5.4.6

Using the dowel pins (h) as a guide, install the flapper valve

assemblies to the pump with the small weight toward the intake side of

each valve.

5.4.7

Secure the port (b or c) to the pump with the screws (a) and washers.

Torque the screws to 22–27 Nm (16–20 ft.lbs.).

Summary of Contents for PDI 2

Page 2: ......

Page 13: ...PD 2 3 Safety Information wc_si000176gb fm 9 ...

Page 25: ...PD 2A 3A Operation wc_tx000592gb fm 21 ...

Page 45: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 41 wc_gr003460 a c f b e d a g g ...

Page 53: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 49 wc_gr003465 wc_gr003464 ...

Page 54: ...Disassembly Assembly Procedures PD Repair wc_tx000590gb fm 50 ...

Page 59: ......