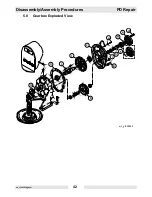

Disassembly/Assembly Procedures

PD Repair

wc_tx000590gb.fm

48

5.12 Testing

See Graphic: wc_gr003464 and wc_gr003465

This procedure requires a vacuum gauge (pn 28755) and a

tachometer.

5.12.1

Check that the mounting hardware for the diaphragm and the valves is

tight.

5.12.2

If the valves are dry, run the pump for a few minutes while adding water

to the pump through the prime plug. Adding water will wet the rubber

gaskets in the valves and provide a better seal while testing.

5.12.3

Reinstall the prime plug.

5.12.4

Start the engine and check the operating speed (rpm) with the

tachometer. Operating speed should be 2700±100 rpm.

5.12.5

Grease the mounting face of the vacuum gauge to ensure a good seal.

Press the gauge over the inlet port.

Note: It is not necessary to keep water in the pump while testing.

Diaphragm pumps do not use a mechanical seal which requires water

in the pump to keep the mechanical seal cool.

5.12.6

Observe the gauge while the pump operates. The gauge reading will

fluctuate slightly as the connecting rod operates the diaphragm. If the

gauge reads 50–55 kPa (15–17 inches Hg) the pump is performing

correctly. If the gauge reads significantly lower than that listed above,

check the diaphragm for cuts or rips like those shown.

Summary of Contents for PDI 2

Page 2: ......

Page 13: ...PD 2 3 Safety Information wc_si000176gb fm 9 ...

Page 25: ...PD 2A 3A Operation wc_tx000592gb fm 21 ...

Page 45: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 41 wc_gr003460 a c f b e d a g g ...

Page 53: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 49 wc_gr003465 wc_gr003464 ...

Page 54: ...Disassembly Assembly Procedures PD Repair wc_tx000590gb fm 50 ...

Page 59: ......