Maintenance

PD

wc_tx000593gb.fm

30

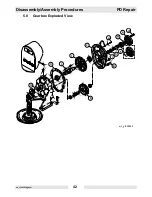

4.11 Lubricating Connecting Rod Bearing

See Graphic: wc_gr003451

Grease connecting rod bearing once a week or every 25 hours of

operation.

Use a hand operated grease gun. Add grease through grease fitting

located behind access hole (j) provided on front cover.

4.12 Cleaning Pump

See Graphic: wc_gr003451

When pumping heavy sludges or water containing large amounts of

dirt and solids, clean the pump often. If allowed to sit in the pump and

dry, these materials will harden and could damage the valves or

diaphragm inside the pump the next time it is used.

When cleaning pump:

4.12.1

Pump clean water through pump for a few minutes after each use to

flush dirt from inside pump and hoses.

4.12.2

Remove dirt from between engine cooling fins to prevent them from

clogging up. This will prevent engine from overheating.

4.12.3

Remove front cover (k) and clean dirt and grease build-up from

connecting rod and inside of front pump cover.

wc_gr003451

j

k

Summary of Contents for PDI 2

Page 2: ......

Page 13: ...PD 2 3 Safety Information wc_si000176gb fm 9 ...

Page 25: ...PD 2A 3A Operation wc_tx000592gb fm 21 ...

Page 45: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 41 wc_gr003460 a c f b e d a g g ...

Page 53: ...PD Repair Disassembly Assembly Procedures wc_tx000590gb fm 49 wc_gr003465 wc_gr003464 ...

Page 54: ...Disassembly Assembly Procedures PD Repair wc_tx000590gb fm 50 ...

Page 59: ......