1. Introduction

Operation and maintenance manual concerns suspended units of type CV-P manufactured by VTS Clima. It consists of basic information and recommendations concerning

the casing, installation, start-up and operation, and if they are obeyed the unit will work properly and without any failures.

The basis of proper and safe operating of the unit is to read thoroughly this manual, use the unit according to descriptions given in it and follow all safety conditions.

The manual should be always near to the device and easily accessible for servicing personnel.

2. Use

Suspended units of type CV-P Clima Top are manufactured in two main versions, which depend on the voltage of power supply of the fan motor:

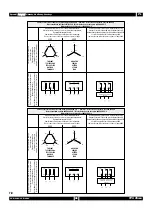

2.1. Compact units CV-P1 (CV-P1-V, CV-P1-HW, CV-P1-HE) with mono-phase fan, which has alternating voltage

of power supply 230V

CV-P1-V

used for simple supply or exhaust of treated air to and from the room

CV-P1-HW

used for supply of treated and heated air by the water heater

CV-P1-HE

used for supply of treated and heated air by the electric heater

Units can operate as only intake, only uptake or in intake-uptake units. Additionally they can be equipped in suppressing section.

2.2. Units with functional sections CV-P1 and CV-P2 with tri-phase fan motor with alternating voltage

of power supply 3x400 V

Units equipped with the various set of functional sections give the opportunity of practical realization of any air treatment process starting from the simplest intake and

uptake ending on the preparation of supplied air in the field of such parameters as temperature (heating – water or electric heaters, cooling – water and freon coolers),

filtration (preliminary and secondary filters), heat recovery (cross-flow exchanger, mixing section), reduction of sound level (suppressors).

Suspended units with functional sections are manufactured in two sizes:

CV-P1

air delivery from 500 to 2600 m3/h

CV-P2

air delivery from 1300 to 4000 m3/h

3. Construction

3.1. Compact units CV-P1-V, CV-P1-HW, CV-P1-HE (230V)

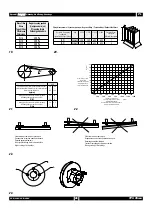

Compact units are made on the basis of blocks constructed without using a framework (fot. 2). Casings, in forms of panel bent in U shape, are made of galvanized steel.

Non-flammable mineral wool 40 mm thick was placed between external and internal metal sheet, what provides proper thermal and acoustic insulation. The casing is closed

with insulated inspection panel, which allows for easy access to components of functional equipment from the bottom if the unit is working in suspended position or from

the top in case of lying position. Every block has four handles, which are used to suspend the unit or place it on the ground. They are also used to connect the block of the

unit and additional sections together.

Functions of air treatment done by the unit are marked with graphic symbols placed on the inspection panels. Air flow is realized by the mono-sided sucking fan with

backward curved blades, which is driven by the mono-phase motor of power supply voltage 230V/50Hz. Units with heaters are equipped with protecting thermostats;

protecting little heaters from overheating in case of electric heater and anti-freeze thermostat in case of water heater.

Multi-phase, backward, regulating and cutting off dampers, used for installation on the air intake and elastic connections used in the places of intake and uptake of air are

delivered in a separate package together with the installation set.

In cases, when reduction of sound generated by flowing air is needed, then units can be additionally equipped with the suppression sections on the intake, uptake or at

both sides of the unit at the same time.

CV-P/230V, CV-P/400V

35

Introduction, Use, Construction

VTS Clima

ENG