Maintenance and cleaning

N.B.

All operations described in this chapter MUST ALWAYS BE PERFORMED BY QUALIFIED PERSONNEL.

Before carrying out any operations on the unit or accessing internal parts, make sure you have disconnected the power

supply. The compressor heads and outlet pipe are usually at high temperature. Take special care when working in the

vicinity of the coils. The aluminium fins are particularly sharp and can cause serious injuries. On completion of maintenance

operations, close the panels and secure them with the fixing screws.

Periodic checks

Every 6 months

It is good practice to conduct periodic checks to ensure that the unit is working properly.

Check that the control and safety components are working properly.

Check that the electrical terminals both in the electrical panel and on the compressor terminal boards are firmly fixed.

Periodically clean the mobile and fixed contacts of the remote contactors.

Make sure that there are no leaks in the in the water circuit.

Check that the flow switch works properly, and clean the metal filter installed on the water pipe.

Check that power is supplied to the guard heaters and that they work properly (once a month).

Inspect the finned coil, and if necessary clean with compressed air in the opposite direction to the airflow. If the coil is

completely clogged, clean it with a low-pressure cleaner, taking care not to damage the aluminium fins.

Check that the fans are properly fixed and balanced.

End of season or unit shutdown

If you intend to shut the unit down for a long period, the water circuit must be emptied so that there is no water left in the

pipes or exchanger. This operation is obligatory if, during seasonal shutdown, you expect the room temperature to fall below

the freezing point of the mixture used (typical seasonal operation).

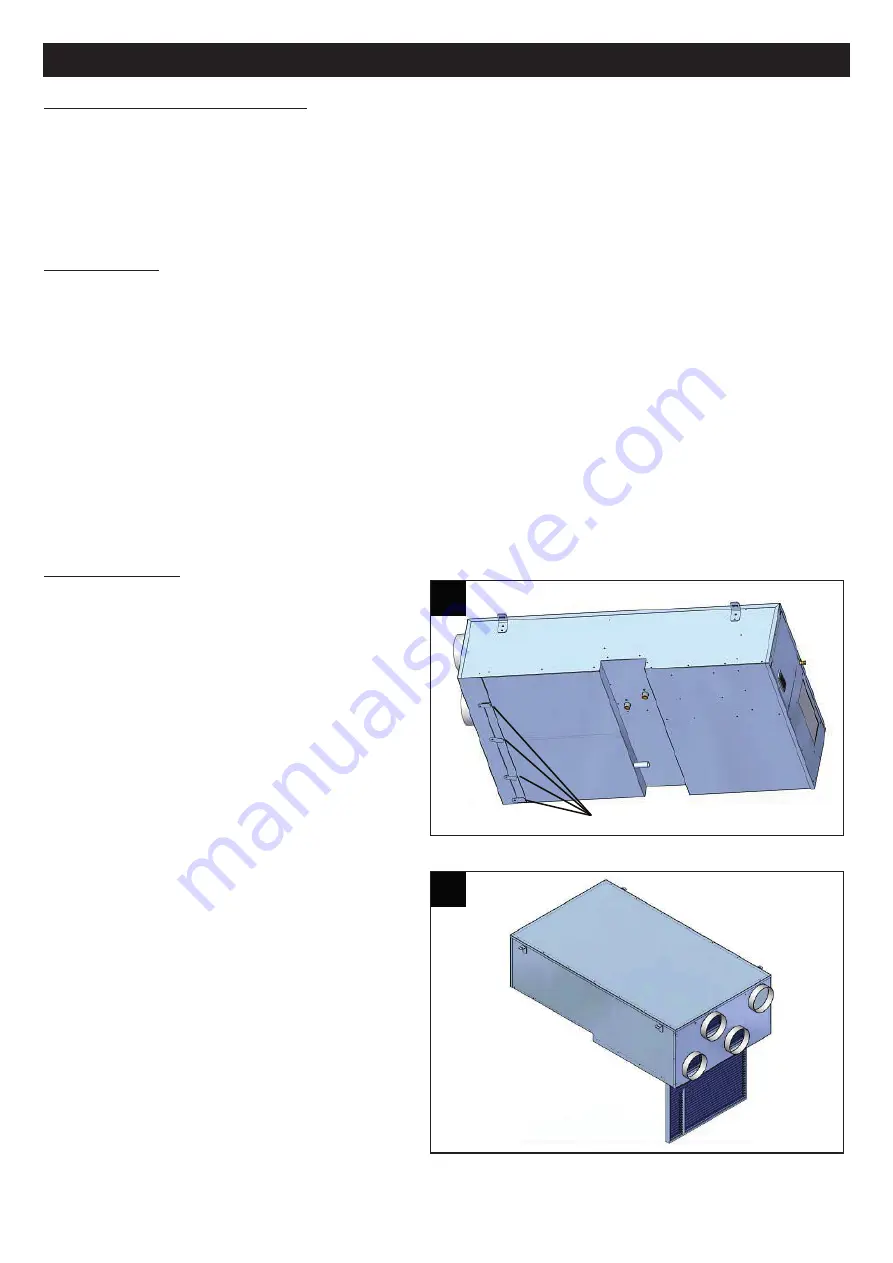

Cleaning the filters

To remove the filters you need to undo the screws

securing the filter bracket as shown in fig.43.

After undoing the screws you can remove the filters as

in fig.44.

N.B.

The filter material can be reused after blow-cleaning or

vacuum-cleaning it. Because of the high efficiency of

the system, however, the filter material cannot be

regenerated more than three or four times, after which

the filter must be replaced.

49

ENGLISH

Viti staffetta blocca filtro

43

43

44

44

Filter bracket screws