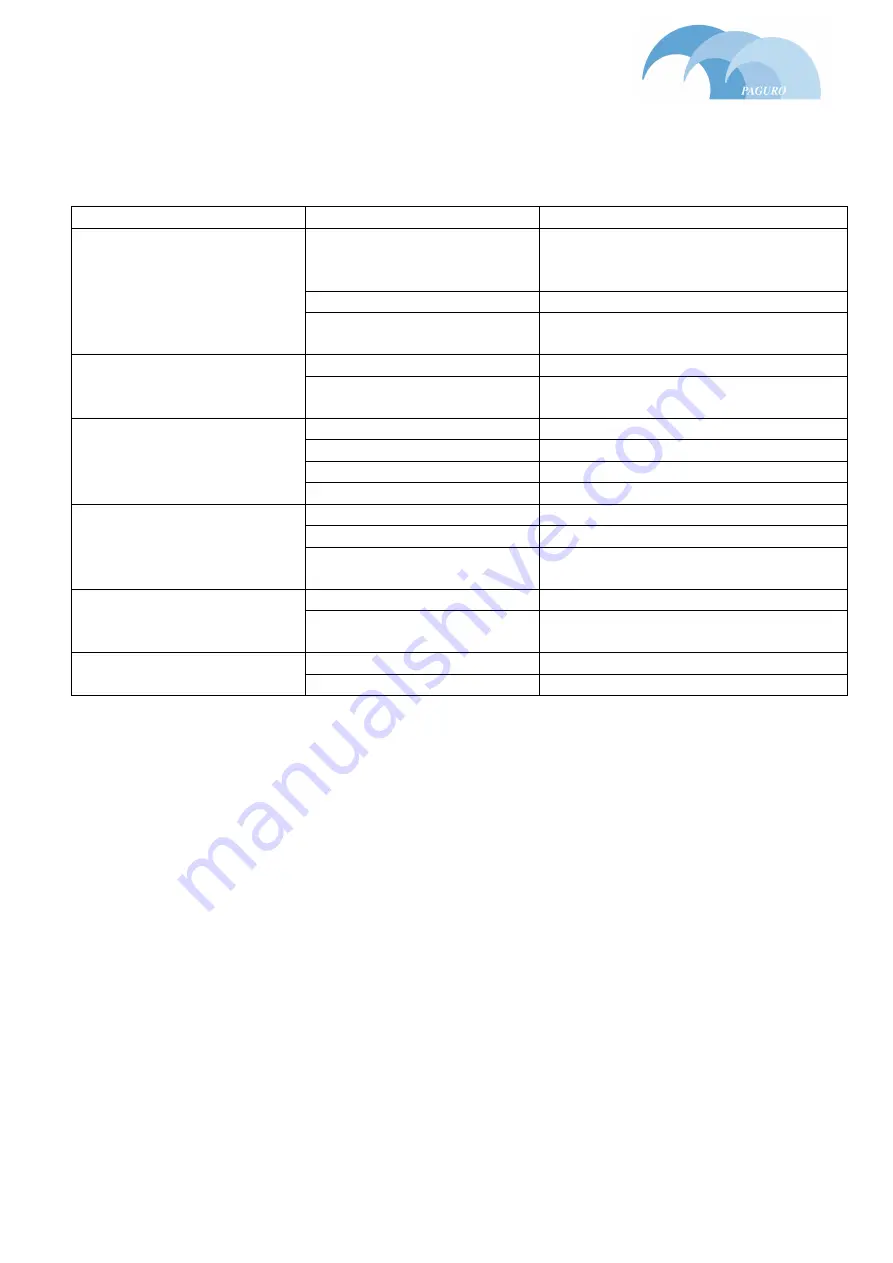

33

FAILURES

Each unit is carefully tested in our factory and the performances are verified; even so a

readjustment can be sometime necessary according to the following suggestions.

PROBLEMS

CAUSES

REMEDIES

1. Low engine speed

1. Check rpm and set at the nominal

value of 3100 rpm without load (3700

for 60 cycles)

2. Faulty capacitor

2. Check and replace

Alternator excitation failure

3. Faulty windings

3. Check that winding resistance as

follows:

1. Engine speed too high

1. Check and adjust rpm

High no-load voltage

(over 240 V)

2. Capacitor with too high

capacity

2. Check and replace

1. Engine speed too low

1. Check and adjust rpm

2. Faulty rotating diodes

2. Check and replace

3. Beak down in windings

3. Check windings resistance as above

Low no-load voltage

(under 230 V)

4. Capacitor with low capacity 4. Check and replace with a new one

1. Low loaded engine speed

1. Dirty fuel filter

2. Overload

2. Check the load indicator

Proper no-load but low under

load voltage

3. Rotating diodes short

circuited

3. Check and replace

1. Loose contacts

1. Check connections

Unstable voltage

2. Uneven rotation

2. Check for uniform rotation speed

(dirty fuel filter)

1. Broken bearings

1. Replace

Noisy generator

2. Loose coupling

2. Check and repair