29

7.4.4

ABSOLUTE MIN FAN SPEED - LP

Select the parameter LP by turning the DHW

temperature control; push MODE button, it is

possible to set the absolute min fan speed that is

related to gas type and boiler output. Modify this

parameter only if strictly necessary.

The value is shown on the display as rpm/100 (i.e.

3600/100 = 36). The set value automatically

modifies the min value of parameter 24.

7.4.5

START-UP FAN SPEED - SP

Select the parameter SP by turning the DHW

temperature control; push MODE button, it is

possible to set the start-up fan speed. Modify this

parameter only if strictly necessary.

The value is shown on the display as rpm/100 (i.e.

3600/100 = 36).

7.4.6

GAS VALVE MAXIMUM SETTING - HH

Select the HH parameter by turning the DHW

temperature control; the boiler starts at the maxi-

mum power, the CO

2

reading should be as shown

in the table below(for LPG see 9.2.

If the CO

2

reading is correct, pass to gas valve

minimum setting (7.4.7). If the CO

2

reading is

incorrect, the maximum gas pressure must be

adjusted as follows:

●

using a suitable screwdriver, very slowly turn

the maximum adjustment screw (see fig. 43) –

clockwise to decrease, counter clockwise to

increase – until the correct value is displayed on

the CO

2

analyser (allow time for the analyser to

stabilise).

IMPORTANT

A GAS SOUNDNESS CHECK MUST BE CAR-

RIED OUT.

7.4.7

GAS VALVE MINIMUM SETTING - LL

Select the LL parameter by turning the DHW

temperature control. The boiler starts at the mini-

mum power, the CO

2

reading should be as shown

in the table above.

If the CO

2

reading is correct, pass to gas valve

final setting (7.4.8). If the CO

2

reading is incorrect,

the minimum gas pressure must be adjusted as

follows:

●

using a 2,5 Allen key, very slowly turn the mini-

mum adjustment screw (see fig. 43) – clockwise

to increase, counter clockwise to decrease - until

the correct value is displayed on the CO

2

analyser

(allow time for the analyser to stabilise).

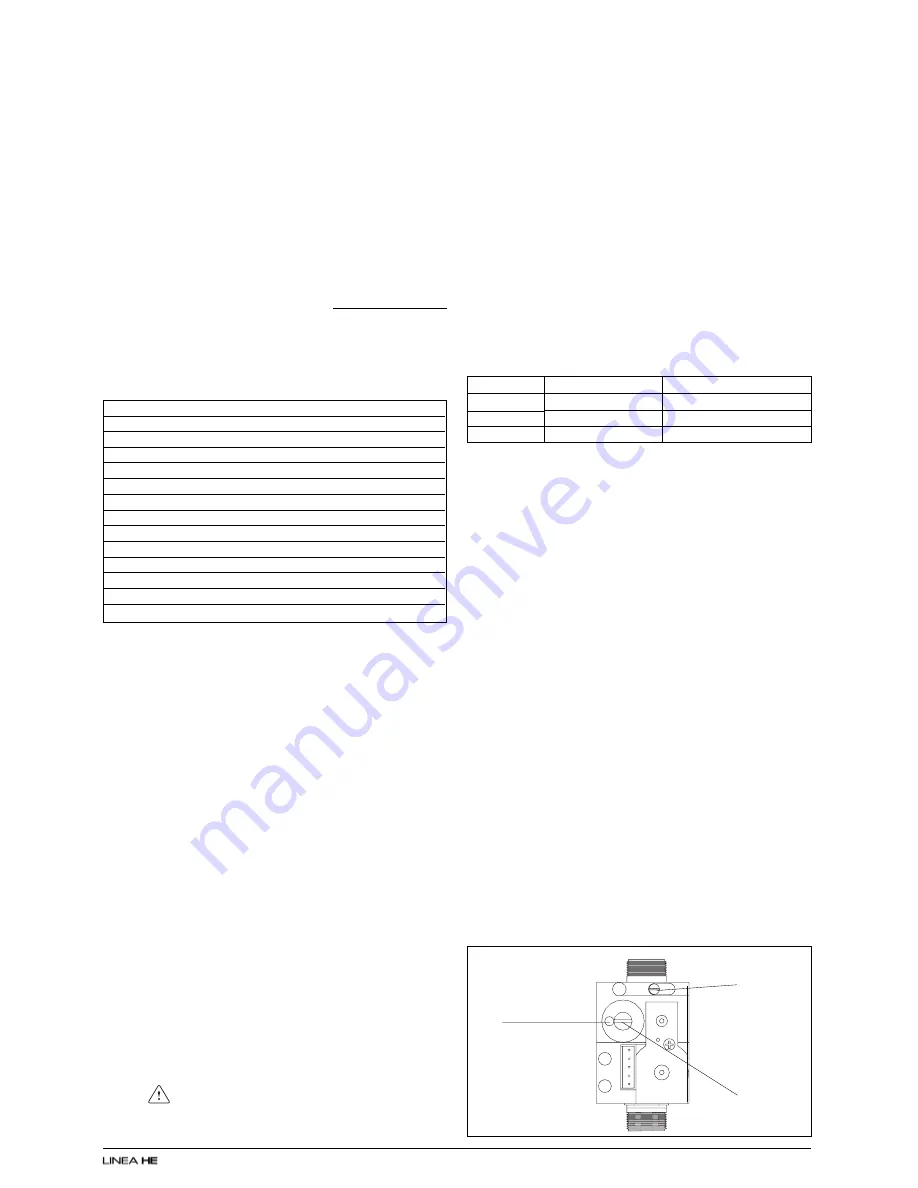

Fig. 43

Maximum

screw

Minimum

screw

7.4

ADJUSTING MODE & ADJUSTING THE GAS VALVE

THE GAS VALVE MUST BE SET-UP OR AD-

JUSTED WITH THE AID OF A PROPERLY CALI-

BRATED FLUE GAS ANALYSER.

Isolate the appliance from the electrical supply

and remove the appliance casing as described in

4.7.1. Set the flue gas analyser to read CO

2

and

insert the probe into the flue analysis test point (

A,

B

fig. 40). Restore the electrical supply to the

boiler and switch on the boiler.

To adjust the gas valve you must first access the

adjusting mode. This mode is only accessible in

STANDBY mode. To access the adjusting mode:

push INFO and MODE buttons at the same time

for 10 seconds to enter the adjusting menu.

The display shows “CodE” (see fig. 41). Push

MODE button and select the adjust parameters

password by turning the DHW temperature control

and confirm it by pushing MODE button. The

following functions are available in this mode.

* Only if outside sensor connected.

7.4.1

GAS TYPE SETTING - 1

Select the parameter 1 by turning the DHW tem-

perature control; push MODE button, it is possible

to set gas type: 1(natural gas) - 2 (LPG), by turning

the DHW temperature control. Push MODE buttom

to store the gas type selected.

7.4.2

BOILER OUTPUT - 2

Select the parameter 1 by turning the DHW tem-

perature control; push MODE button, it is possible

to set the boiler output: 26 (25 kW) - 30 (30 kW) -

34 (35 kW), by turning the DHW temperature

control. Push MODE buttom to store the gas type

selected.

ATTENTION

Gas type and boiler output

must be

according to

the boiler design specification.

Vokera has no responsability if the gas type and

boiler output are set not according to the appliance

specification.

7.4.3

ABSOLUTE MAX FAN SPEED - HP

Select the parameter HP by turning the DHW

temperature control; push MODE button, it is

possible to set the absolute max fan speed that is

related to gas type and boiler output. Modify this

parameter only if strictly necessary.

The value is shown on the display as rpm/100 (i.e.

3600/100 = 36).

For Linea 28HE and 32HE it is necessary to

adjust the parameter 23 (see 7.4.9).

Power

Linea 28HE

Linea 32HE

Linea 36HE

CO

2

@ min

9.3%

9.0%

9.0%

CO

2

@ max

9.0%

9.0%

9.0%

Par.

Action

01

set gas type

02

set boiler power

10

set DHW type

03*

type of building

45*

climatic curve selection

HP

absolute max fan speed selection

LP

absolute min fan speed selection

SP

start-up fan speed

HH

force burner at max power

LL

force burner at min power

MM

force burner at medium power

23

max output CH (fan speed)

24

min output CH (fan speed)

Compensation

pipe connection