www.voestalpine.com/strassensicherheit

voestalpine Krems Finaltechnik GmbH

ONE STEP AHEAD.

Assembly instructions KB 1 RH3 on pile-drivable subgrade

page 11 of 13

9. Shims

Generally, the vehicle barrier system should be installed so that shims are not

required. However, if shims are required due to conditions on site, then the following

points must be observed:

·

The regulation centre distance of the posts is to be retained as far as possible.

·

If the longitudinal elements have to be sawn, it is to be ensured that the cut is

made clearly.

·

The cut is to be executed so that the swarf cannot damage the hot-dip

galvanised sections (risk of extraneous rust or damage to the coating).

·

The burrs are to be removed and the cut area is to be protected against

corrosion with cold-galvanizing paint in accordance with EN ISO 1461.

·

The hole pattern for joining a shim must correspond to the regulation design

and the gaps to the corners may not be smaller than those of the regulation

design.

·

Flame cutting is generally impermissible for installation work!

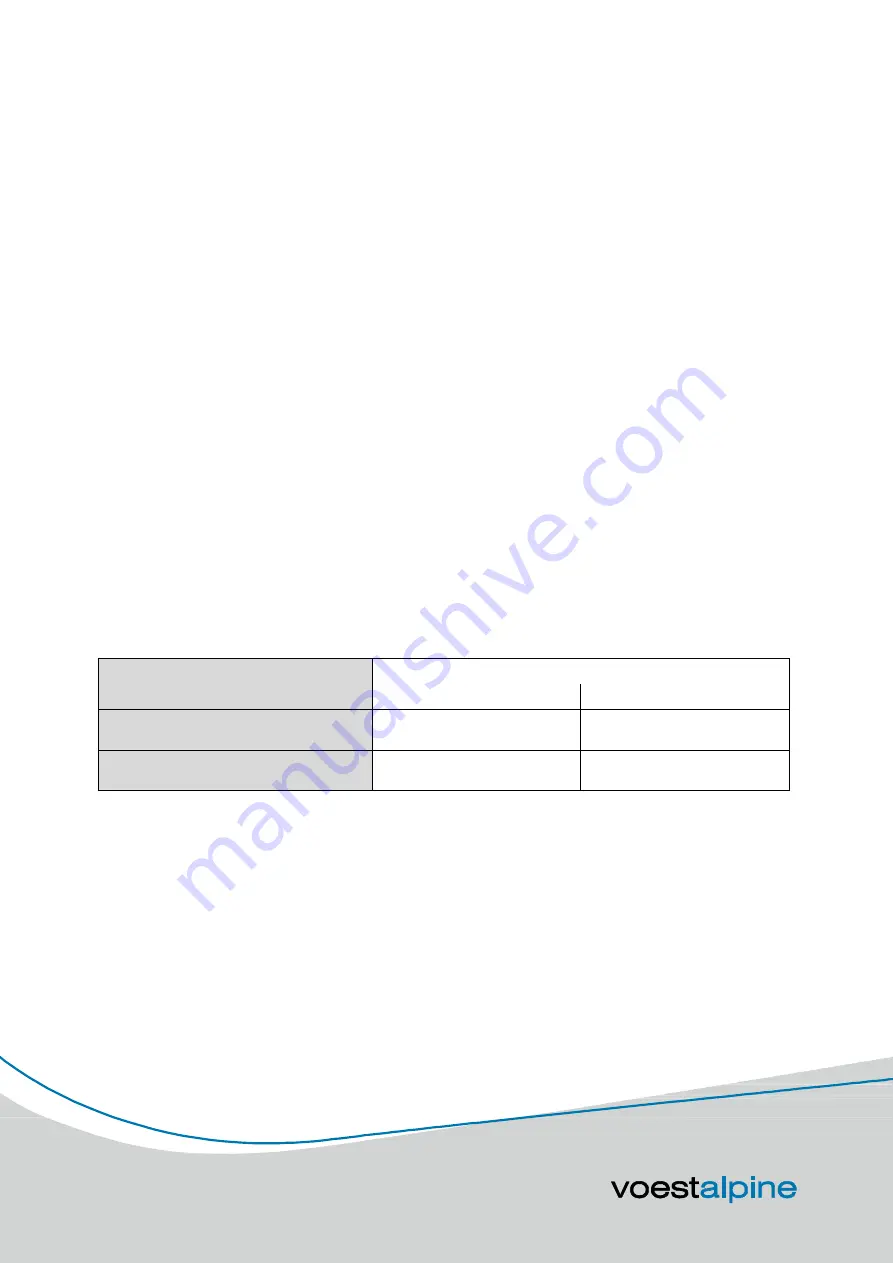

10. Torques for threaded connections

Thread / strength class

Torque

min.

max.

M10 / 4.6

10 Nm

17 Nm

M16 / 4.6

35 Nm

70 Nm

It is to be ensured that a sufficiently large bearing surface is given in the clamped

area for tightening unscheduled prestressed threaded connections when applying the

above specified torques.