22

Test Connection Safety Precautions

The Vitrek 944i Dielectric Analyzer is capable of generating up to 8000 VAC RMS and 10000 VDC depending on the

configuration. It is extremely important that the user observe safe operating procedures to avoid contact with these

DANGEROUS VOLTAGE LEVELS

. In addition to using common sense handling techniques for high voltage operation, the

following precautions should be taken into consideration whenever operating the 944i:

1. Use only high voltage rated test lead material for connection to the high voltage output terminal.

2. Inspect high voltage lead regularly for signs of wear and abrasion.

3. Avoid contact with the high voltage output (terminal, leads and DUT) at all times during high voltage testing.

4. Always ensure that the 944i is properly earth grounded before applying power.

Measurement Terminals

The stimulus/measurement terminals of the 944i are recessed and insulated to prevent operator exposure to high voltages. For

connection to V hi terminal, always use an insulated (sheathed) banana plug with adequate insulation rating. Never handle the

plug or test lead while high voltage is applied.

Dielectric Testing (VAC, VDC and I/R)

All dielectric tests are performed from the 944i's V HI and V LO terminals. The V HI terminal is floating, while the V LO

terminal remains relatively close to chassis ground at all times.

Low Resistance Testing

All low resistance tests are conducted between the V LO terminal of the 944i and its chassis sense terminal. It is recommended

that a low resistance test be conducted on earth ground devices to verify ground continuity prior to dielectric testing.

Connecting to Devices with Earth Grounds

Earth grounded devices must be isolated from earth ground when conducting dielectric strength tests with the 944i. This will

insure that all leakage current flows through the 944i and is properly detected. As an added safety design, the V LO and Chassis

Sense terminals of the 944i each feature dual redundant M.O.V. clamping, to keep them at a low potential (18V max).

When testing devices that are equipped with an earth ground plug, it is always recommended that the user first conduct a

continuity test between the DUT's earth ground plug and any exposed conductive surfaces (chassis). The 944i is capable of

conducting this test in several different modes. When a high current (3 to 40 amps) ground continuity test is required, the Vitrek

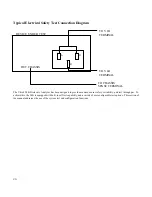

930i is recommended. The connection to the DUT for continuity testing from the 944i is as follows:

1. Connect the V LO terminal of the 944i to the DUT earth ground plug.

2. Connect the Chassis Sense terminal of the 944i to any exposed conductive surface of the DUT's chassis.

Note: All

continuity (low resistance) measurements on the 944i are made between the V LO terminal and the Chassis Sense

terminal.

4. The V HI terminal of the 944i is normally connected to the two electrical prongs of the device under test. In this

configuration the 944i will be checking for continuity between the DUT's earth ground plug and DUT chassis, as well as

current flow between the DUT's electrical circuit and its’ earth ground plug.