19

7602050

FIG.3

FIG.5

FIG.4

NOTE:

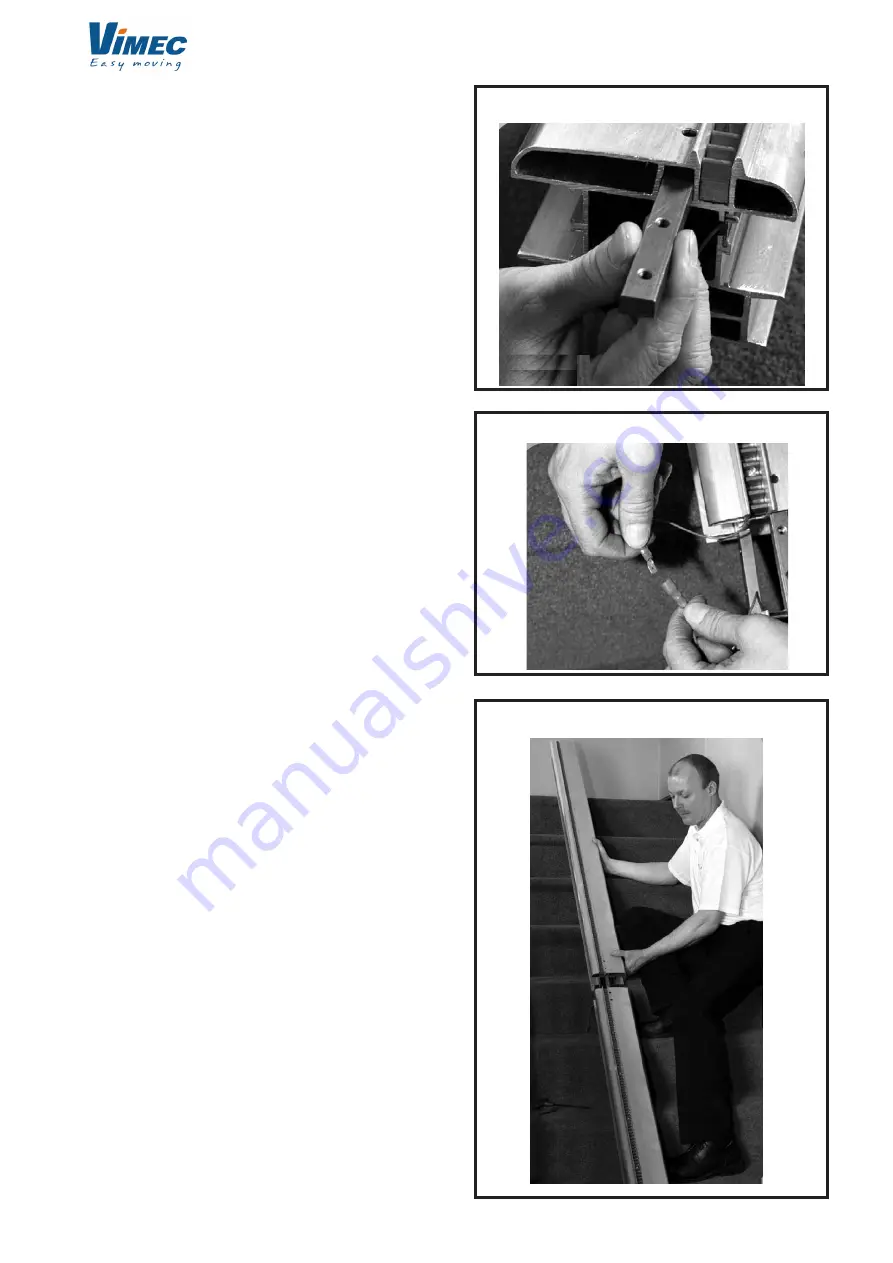

Ensure that the splice bars are positioned in

the track in the correct orientation. The splice bar has

three flat faces and one sloping face. The sloping face

MUST be positioned against the sloping face on the

extrusion as shown in (Fig. 3).

2.3-

Position the top section of track adjacent to

the bottom section of track (Fig. 4).

2.4-

For older machines: near the junction connect

the spade terminal connectors for the busbar charging

strip (Fig.5).

- For recent machines:

Kits now include a short copper strip that must be

placed across the track/busbar joint.

This replaces the copper adhesive tape and the

internal connection with the cables that were used

previously.

The installation instructions for this new connection

are explained below, and a copy is enclosed in each

installation kit.

1. Assemble the track as usual.

2. Slide the top of the load bar including the plastic for

approx. 100 mm.