SECTION TSM

845.1

ISSUE

C

PAGE 9 OF 13

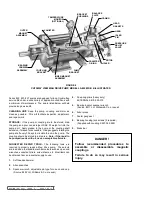

BEARING HOUSING

DISASSEMBLY Of BEARING HOUSING

The bearing housing features two grease packed tapered

roller bearings (TRB) along with a one-piece outer magnet

assembly with shaft. The unit may be greased externally

using the grease fitting. See

figure 15

if further assembly is

required and proceed as follows:

1.

Cover the open end of the outer magnet with a piece of

sheet metal. This will keep foreign material out of magnet

area and protect the magnets. Set the assembly face

down with the shaft pointing up and remove jackscrews.

2.

Bend the lockwasher tab up and gently tap the locknut in

a counterclockwise direction with a punch until loose. (If

this does not work, place a key into shaft of outer magnet.

Use 1.875” wrench to hold outer magnet and a spanner

wrench to loosen lock nut. Remove the locknut and

lockwasher. Then lift the bearing carrier off the shaft of

the outer magnet assembly.

3.

Back out the (2) setscrews holding the bearing cap then

remove the bearing cap with a spanner wrench. The

inner and outer spacers, outer TRB and inner TRB cone

should all slide out of the bearing housing.

4.

One lip seal is pressed into the bearing cap and the other

is pressed into the bearing housing. Do not remove

unless replacing.

5.

If inner TRB is worn or damaged, remove cup of inner

TRB.

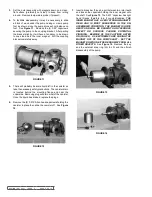

ASSEMBLY Of BEARING HOUSING

Depending on the condition of the bearings either replace or

recondition existing bearings by cleaning and packing with a

heavy duty grease. Replace the lip seals if necessary.

1.

Place the bearing carrier down with the cast surface

up. Install the inner lip seal (if removed). Then install

the cup (if removed) of the inner TRB and the cone into

the bearing housing bore. Insert the inner bearing spacer

(longer one of the two) and the outer TRB into the bore.

Place outer spacer on top of the cone of the outer TRB.

2.

The outer end cap houses the second lip seal. If the

seal is in good condition, slide the endcap over the outer

spacer then thread into bearing housing. Center the inner

spacer so the shaft will slide through the two bearings.

Thread in the end cap until it makes contact with the outer

TRB. Tighten the endcap by hand until tight and secure in

position with the (2) setscrews.

3.

Insert the outer magnet shaft through the bearings and

the spacers. When the shaft is in the proper position

there should be approximately 0.75” between the magnet

and the housing. See

figure 15

.

4.

Place the lock washer onto the shaft then thread the

locknut onto the shaft. Tighten locknut to 50 Ft-Lbs then

bend over a lockwasher tab.

5.

Tighten the endcap to 75 Ft-lbs and rotate bearing housing

2-3 turns. Back off the end cap and then retighten to 75

Ft-Lbs. Tighten the two .31” setscrews onto the endcap.

Use the grease fitting to fill the bearing chamber with

additional grease.

INSTALLATION Of BUSHINGS

CARBON GRAPHITE:

When installing carbon graphite bushings, extreme care must

be taken to prevent breaking. Carbon graphite is a brittle

material and easily cracked. If cracked, the bushing will quickly

disintegrate. Using a lubricant on the bushing and mating part

will help in installation. The additional precautions listed below

must be followed for installation:

1.

An arbor press must be used for installation.

2.

Be certain bushing is started straight.

3.

Do not stop pressing operation until bushing is in proper

position, starting and stopping will result in cracking

bushing.

4.

Check bushing for cracks after installation.

SILICON CARBIDE:

When installing silicon carbide bushings into a metal part

the mating part must be heated to 600ºF (preferably in an

oven). Bushing must be quickly put into the proper position

before the mating part cools down and the bushing heats up.

FAILURE TO FOLLOW THIS PROCEDURE WILL RESULT

IN CRACKED BUSHINGS.

fIGURE 15

COVER END Of MAGNET

WITH PIECE Of SHEET

METAL APPROX. 10” x 10”

OUTER

MAGNET

ASSEMBLY

OUTER

SPACER

BEARING

HOUSING

OUTER BEARING

SET SCREWS (2)

LOCK WASHER

LOCK NUT

END CAP

LIP SEAL

.75 REf

INNER SPACER

GREASE fITTING

INNER BEARING