SECTION TSM

845.1

ISSUE

C

PAGE 11 OF 13

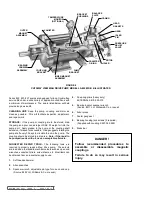

2.

Place a spacer under pump so the foot sits flat and clamp

foot to the table. Install one of the secondary O-Ring

seals onto the pump pilot then slide the coupling bracket

up to pump and bolt together.

3.

Install two threaded rods into the bracket on the other

end. Insert the (2) jackscrews into their holes of the

bearing housing and thread in completely. Install other

secondary O-ring onto the bearing housing pilot. Support

the bearing housing assembly from over head then slide

onto the (2) threaded rods. Balance the assembly and

glide outer magnet onto canister until jackscrews come

to rest in the two counter bored holes on the bracket.

BE

CAREFUL TO CENTER THE OUTER MAGNET WHILE

STARTING TO ENGAGE CANISTER.

Depending

on lengths of magnets the unit may be drawn in as the

jackscrews are removed or may require pushing in.

Evenly back off the jack screws until the housing is

approximately 1” from the bracket then remove the over

head support and finish backing off the jack screws. The

housing may require a slight lift to get into the pilot of the

bracket. Secure with (2) capscrews then remove the rods

and install final (2) capscrews.

ADJUSTING HEAD GASKET END

CLEARANCE

Use either of the following procedures to properly adjust the

end clearance, when replacing gaskets.

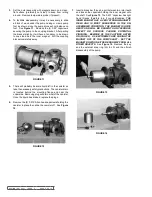

PROCEDURE A:

With the casing secured to the bracket and balance plate in

position, slide the rotor and shaft into the casing. Insert the

feeler gage of the proper thickness into the port and between

two rotor teeth. Install one .015” and .007” gasket onto the

head. With the idler on idler pin, place head into the pump

casing. With capscrews tight, the feeler gage should fit snugly;

otherwise gaskets should be added or removed until the

proper clearance is attained. See

figure 19

.

fIGURE 19

fIGURE 20

PROCEDURE B:

If the pump is in the pipeline and not accessible through ports,

remove the head and remove gaskets. Put the head back

on and measure the gap as shown. See

figure 20

. After

determining the gap between head and casing, select a

combination of gaskets with approximately 25% more total

thickness than the feeler gage plus required end clearance.

See

figure 18 on page 10.

Note: gaskets will compress

when head is tightened down. Remove head, install all

gaskets and the O-ring, and then install head. Tighten the

head capscrews and then check the pump by making sure

the pump turns over freely by hand.

ASSEMBLY: D SERIES COUPLING

1.

Remove any foreign material attached to the magnets.

Place key in pump shaft and slide inner magnet on shaft

until it comes to rest against shoulder on shaft. Insert

washer, lockwasher and capscrew into end of magnet

and tighten. May require inserting brass bar into port to

block rotor from turning. Install O-ring into face of pump

bracket then slide canister over inner magnet and secure

with the capscrews.

DANGER !

follow these directions exactly to avoid

injury to self or damage to pumping unit,

be extremely careful to keep inner & outer

magnets at least (1) foot apart until step

3. Do not allow magnets to engage in any

other fashion. Be aware of health hazards

listed on (page 2).

DANGER !

Before starting pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may

result in serious injury or death.