SECTION TSM

845.1

ISSUE

C

PAGE 4 OF 13

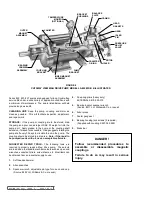

fIGURE 4

CUTAWAY VIEW MAG DRIVE PUMP, MODEL LS-825 MD-D B ILLUSTRATED

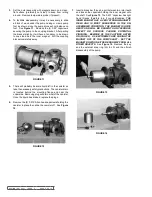

Series 825, 823, 827 pumps are designed for long, trouble-free

service life under a wide variety of application conditions with

a minimum of maintenance. The points listed below will help

provide long service life.

CLEANING UNIT:

Keep the pump, coupling and motor as

clean as possible. This will facilitate inspection, adjustment,

and repair work.

STORAGE:

If the pump or coupling are to be stored, drain

the pump and pour non-detergent SAE 30 weight oil into the

pump port. Apply grease to the pump or the coupling shaft

extension, if present or accessible. Viking suggests rotating the

pump shaft every 30 days to circulate the oil in the pump. The

coupling should be stored in a dry area.

Note: if the liquid to

be pumped reacts with oil, use an acceptable alternate.

SUGGESTED REPAIR TOOLS:

The following tools are

required to properly repair a Mag Drive pump. These tools

are in addition to standard mechanics tools such as open end

wrenches, socket set, pliers, screw drivers, etc. Most items can

be obtained from an industrial supply house.

1.

Soft headed hammer

2.

Allen wrenches

3.

Spanner wrench, adjustable pin type for use on end cap

(Source: #482 J.H. Williams & Co. or equal)

4.

Snap ring pliers (heavy duty)

EXTERNAL 2-810-029-375

5.

Bearing locknut spanner wrench

(Source: #471 J.H. Williams & Co. or equal)

6.

Arbor press

7.

Feeler gauge set

8.

Bearing housing jack screws (2 required)

(Supplied with coupling 2-297-022-999)

9.

Brass bar

DANGER !

follow recommended procedures to

assemble or disassemble magnetic

couplings.

failure to do so may result in serious

injury.

PRESSURE

RELIEf

VALVE

ROTOR

HEAD

IDLER

PIN

CASING

HEAD

GASKETS

IDLER

INNER MAGNET

ASSEMBLY

BEARING

CARRIER

ASSEMBLY

OUTER

MAGNET

ASSEMBLY

CANISTER

BRACKET

BUSHINGS

TEMPERATURE

MONITOR

(OPTIONAL)

BALANCE

PLATE

COUPLING

BRACKET

CANISTER

O-RING

PUMP

BRACKET