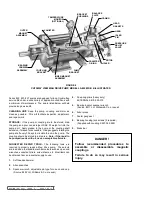

SECTION TSM

845.1

ISSUE

C

PAGE 7 OF 13

Before further disassembly of the pump can occur, the pump

must be separated from the coupling. Refer to

DISASSEMBLY: MD-D SERIES COUPLING on page 7

before proceeding with step 6.

6.

After the inner magnet is removed from pump shaft,

remove the external snap ring from pump shaft (LQ &

LS only). The rotor and shaft may now be removed by

tapping on the end of shaft with a soft face hammer or, if

using a regular hammer, use a piece of hardwood

between the shaft and hammer.

7.

Because the balance plate is designed to be used in

either rotation, mark the balance plate prior to removal.

Remove balance plate by pulling out of casing.

Examine the casing for wear, particularly the area between

the ports. All parts should be cleaned and checked for wear

or damage before pump is assembled.

When making major repairs, such as replacing a rotor and

shaft, it is advisable to also install a new head and idler pin,

idler and bushing, bracket bushings, balance plate and head

gaskets. See

INSTALLATION Of BUSHINGS on page 9.

PUMP ROTATION

Viking Mag Drive

®

pumps are directional. If it is necessary to

rotate in the opposite direction, the pump must be disassembled

through step 7. Rotate the balance plate 180º and reinstall

into the casing. Second, the pipe plug (item 23 for LQ & LS,

item 24 for Q & QS) must be on the suction side of the head.

Remove the pipe plug and reinstall in the other similar hole in

the head Follow the procedure for pump assembly. Reverse

the relief valve orientation so the adjusting cap points towards

suction port.

PORT ARRANGEMENT

Standard configuration (as viewed from the pump shaft) is right

angle porting (LQ, LS & Q) – the suction port for clockwise

rotation is at 9 o’clock. The top port (at 12:00) is the standard

discharge port. If the desired configuration is different and

the rotation is still clockwise, mark the suction port, remove

the (8) bracket to casing capscrews and carefully rotate the

casing on the bracket pilot then reinstall the capscrews. The

QS features opposite ports and can not be rotated because

the flanged ports will interfere with the pump bracket foot.

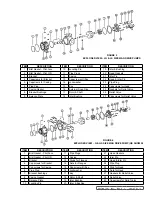

DISASSEMBLY: MD-D SERIES

COUPLING

.

1.

Install the two jackscrews (2-297-022-999) into the

bearing housing. See

figure 7 on page 6

, and

figure

8

. Remove two 0.50” capscrews and thread a 0.50” NC x

8” threaded rod into these holes. Remove other two 0.50”

capscrews.

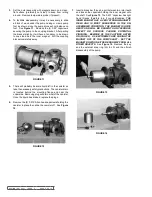

2.

Turn in the two jackscrews evenly, backing the bearing

housing away from the bracket. See

figure 8

. Install a

strap from overhead to support the housing and outer

magnet when the housing is approximately 1.50” away

from the bracket. See

figure 9

. Continue turning the

jackscrews until the outer assembly comes out freely.

See

figure 10

.

fIGURE 8

CAUTION !

Magnet sets are extremely powerful.

Serious injury may result if proper

procedures are not followed.

fIGURE 9

fIGURE 10