C. Pump is noisy.

1.

Pump is being starved (heavy liquid cannot get to

pump fast enough). Increase suction pipe size or

reduce length.

2.

Pump is cavitating (liquid vaporizing in the suction

line). Increase suction pipe size or reduce length. If

pump is above the liquid, raise the liquid level closer to

the pump. If the liquid is above the pump, increase the

head of liquid.

3.

Check alignment.

4.

May have a bent shaft or rotor tooth. Straighten or replace.

5.

Relief valve chatter. Increase pressure setting.

6.

May have to anchor base or piping to eliminate or

reduce vibration.

7.

May be a foreign object trying to get into the pump

through the suction port.

8. Mag Drive pumps ONLY:

The magnetic coupling has

decoupled. Shut off and let cool, then restart.

D. Pump not up to capacity.

1.

Starving or cavitating. Increase suction pipe size or

reduce length.

2.

Strainer partially clogged.

3.

Air leak in suction piping or along pump shaft.

4.

Running too slowly. Check the motor is running at the

correct speed and that it is wired correctly.

5.

Bypass line around pump partially open.

6.

Relief valve set too low or stuck open.

7.

Pump is worn out.

8.

Too much end clearance.

9.

Head position incorrect. See

Figure A3

.

E. Pump takes too much power.

1.

Running too fast. Verify the motor speed, reducer ratio,

sheave size, and other drive components are correct

for the application?

2.

The liquid is too viscous for the size of the unit. Heat

the liquid to reduce viscosity, increase the pipe size,

slow down the pump, or use a larger motor.

3.

Discharge pressure higher than calculated. Verify with

a pressure gauge. Increase size or reduce length of

pipe, reduce speed (capacity), or get bigger motor.

4.

Packing gland drawn down too tight.

5.

Pump misaligned.

6.

Extra clearance on pumping elements may not be

sufficient for operating conditions. Check parts for

evidence of drag or contact in pump and increase

clearance where necessary.

7.

System pressure relief valve is set too high.

8.

Bushings have locked to shaft or pin, or the liquid has

set up in the pump.

F. Rapid Wear.

On most applications the pump will operate for many

months or years before it gradually loses its ability to

deliver capacity or pressure. Examination of such a pump

would show a smooth wear pattern on all parts. Rapid

wear, occurring in a few minutes, hours or days, shows

up as heavy grooving, galling, twisting, breaking or similar

severe signs of trouble. See

Rapid Wear Table

.

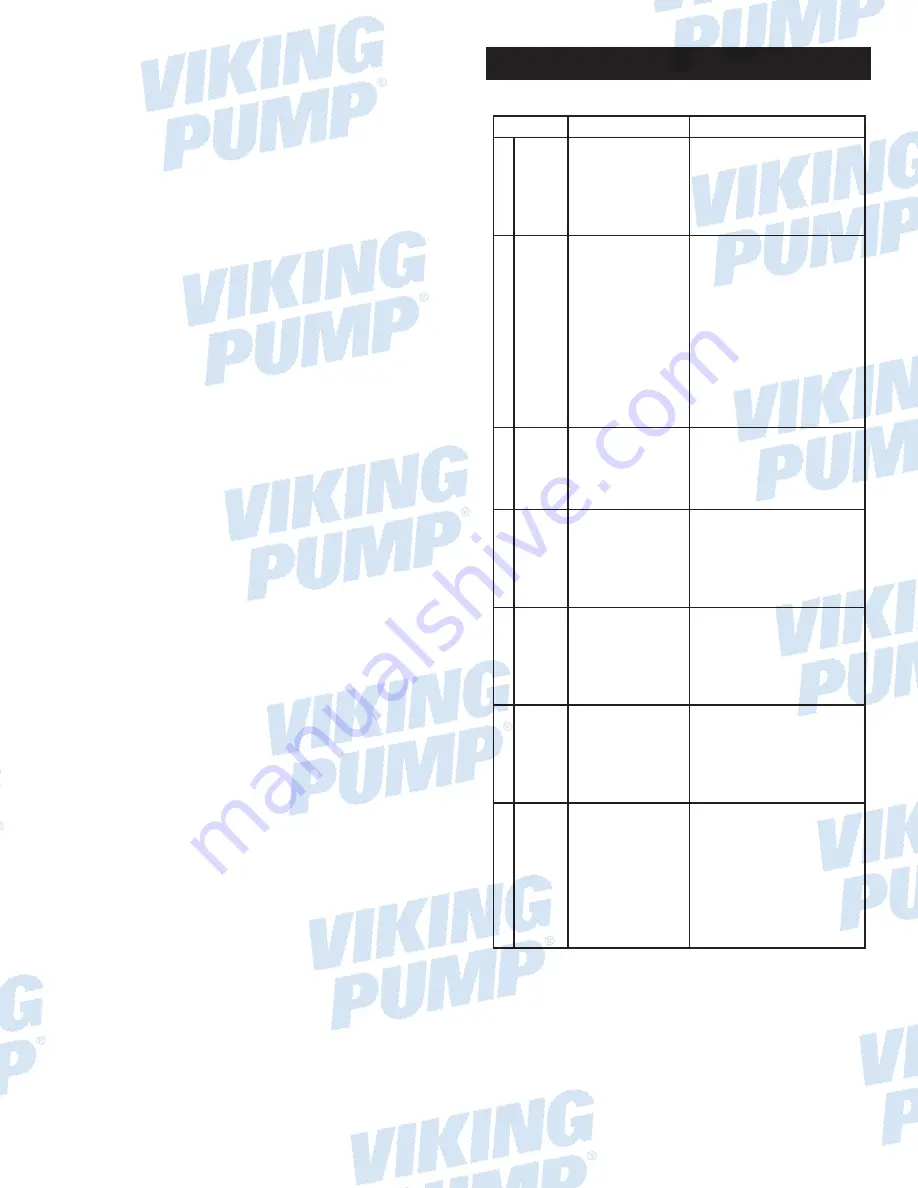

RAPID WEAR

RAPID WEAR TABLE

CAUSE

EVIDENCE

POSSIBLE SOLUTION

1

ABRASIVES

Gouges or marks made

by large, hard particles;

a rapid wearing away

of bushings from very

small abrasives; or

anything in between.

Flush the system with the pump

removed. Install strainer in suction

line. Most abrasive objects and

particulate is removed after a few

cycles (or days) of flushing.

2

CORROSION

Rust, pitting or metal

appears to be “eaten”

away.

Check the Viking General

Catalog Liquid List for materials

of construction recommendation.

Consider whether all of the

materials used in pump

construction were attacked;

consider other materials used in

the system to determine how they

resisted the liquid. Check to see

whether or not the liquid has been

contaminated to make it more

corrosive than anticipated.

3

EXCEEDING

OPERA

TING

LIMITS

Noisy operation,

broken bushings,

twisted shaft, parts

show evidence of high

heat (discoloration).

Review General Catalog for

operating limits on particular model

involved.

4

INSUFFICIENT

EXTRA

CLEARANCE

Pump may stall.

Evidence of heavy

contact between end of

rotor teeth and head or

other parts.

Increase end clearance and/

or contact your Viking Pump

®

representative with details of the

application, so that information

regarding proper extra clearance

may be provided.

5

LACK OF

LUBRICA

TION

Noisy bearings,

localized heating at

bearings or lip seal,

smoke, rapid bushing

wear.

Be sure all grease fittings are

greased before starting, and

instructions for lubrication of

drive equipment are followed;

consider use of auxiliary lubricating

equipment.

6

MISALIGNMENT

Wear on only one part

of a surface, e.g., one

side of the casing, one

side of the packing

gland, only a portion of

the face of the head.

Double check alignment of drive

equipment and piping. Check the

alignment under conditions as

close to operating conditions as

possible.

7

RUN DR

Y

Pump stalls because

parts have uneven

expansion caused by

frictional heat; galling

between surfaces

having relative motion;

seal seats and idler

pins changing color

because of high heat.

Be sure there is liquid in the

system at the time of start up.

Provide some kind of automatic

alarm or shut-off if supply tank

runs dry.

TSM 1741 | Issue B | Page 17 of 20

© 2019 Viking Pump, Inc. • Cedar Falls, IA

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.

© Viking Pump, Inc.