■ The flue system must be sized in accordance with the internal cross-

section and height, and if required also according to the thermal

resistance and the internal surface, to ensure that the flue gases will

be extracted to the outside under all operating conditions and so that

no dangerous pressures can be created in any rooms.

■ Flue gases from combustion equipment fired by liquid or gaseous

fuels can be piped into chimney stacks or into flue pipes.

■ Flue pipes mounted on the side of buildings must be at least

20 cm away from windows.

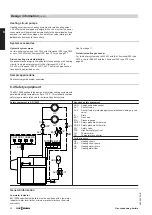

■ Outlet points from chimneys or flue pipes must meet the following

conditions:

– They must protrude at least 40 cm above the roof ridge or must be

at least 1 m away from the roof surface.

– They must protrude at least 1 m above roof structures and open-

ings to rooms, if their distance from chimneys and flue pipes is less

than 1.5 m.

– They must protrude at least 1 m above unprotected structural parts

made from combustible material, except roof coverings, or they

must be at least 1.5 m away from such structures.

– Further alternative requirements may apply if a risk or unaccept-

able disturbance is expected.

■ For combustion equipment with a combustion heating output of

1 MW or more, the flue outlet must protrude at least 3 m above the

highest point of the roof ridge and must be at least 10 m above

ground level.

■ With a roof slope of less than 20°, relate the height of the boiler flue

connection to a fictitious roof ridge, the height of which should be

calculated on the assumption of a roof slope of 20°.

We recommend you seek advice from your local flue gas inspector.

x < 1.5 m

a

≥ 1.0 m

if

then

≥ 1.0 m

≥ 0.4 m

≥ 1.0 m

≥ 1.0 m

x < 1.5 m

a ≥ 1.0 m

Flue systems for condensing boilers

The Vitocrossal cools the flue gases down to the condensing range,

depending on the heating water return temperature. They then leave

the system with a relative humidity of 100 %. Subject to system con-

ditions, the flue gas temperature can reach up to 110 °C. The low flue

gas temperature and the resulting low updraught plus the additional

condensation of the flue gases inside the flue system make it a neces-

sity for the flue system manufacturer to calculate the flue, which must

also be made from suitable materials.

In addition, special requirements apply to the design and positioning

of the flue system of condensing combustion systems.

If installing the Vitocrossal in an attic, (type B33 to TRGI 2008), the flue

can be routed as a vertical roof outlet (see stainless steel flue systems

in the Vitoset pricelist).

Condensing boilers must be connected to tested and approved flue

pipes. Flue pipes must have Building Regulations approval.

Flue gas temperature sensor

According to the "Guideline for flue pipe approval" point 3.12, only

components which are approved parts of the flue pipe system may be

connected to or be incorporated into flue pipes serving condensing

boilers. Therefore, apertures for the installation of flue gas temperature

sensors must form part of the manufacturer's system design and

should be tested together with the flue pipe.

Subsequent drilling and

fitting of third party components is not permitted.

The Vitocrossal condensing boilers may also be connected to mois-

ture-resistant chimneys. According to EN 13384, the chimney manu-

facturer must provide a calculated verification, giving due considera-

tion to the flue gas values of the boiler (see specification in the respec-

tive datasheet).

The flue pipes must be raised above roof level inside an existing or a

newly constructed chimney (casing without internal pipe). We would

recommend contacting a flue pipe manufacturer during the design

stage because of the size and design of the chimney.

Design information

(cont.)

Gas condensing boilers

VIESMANN

25

5822 449 GB

8