14

Fig. 6

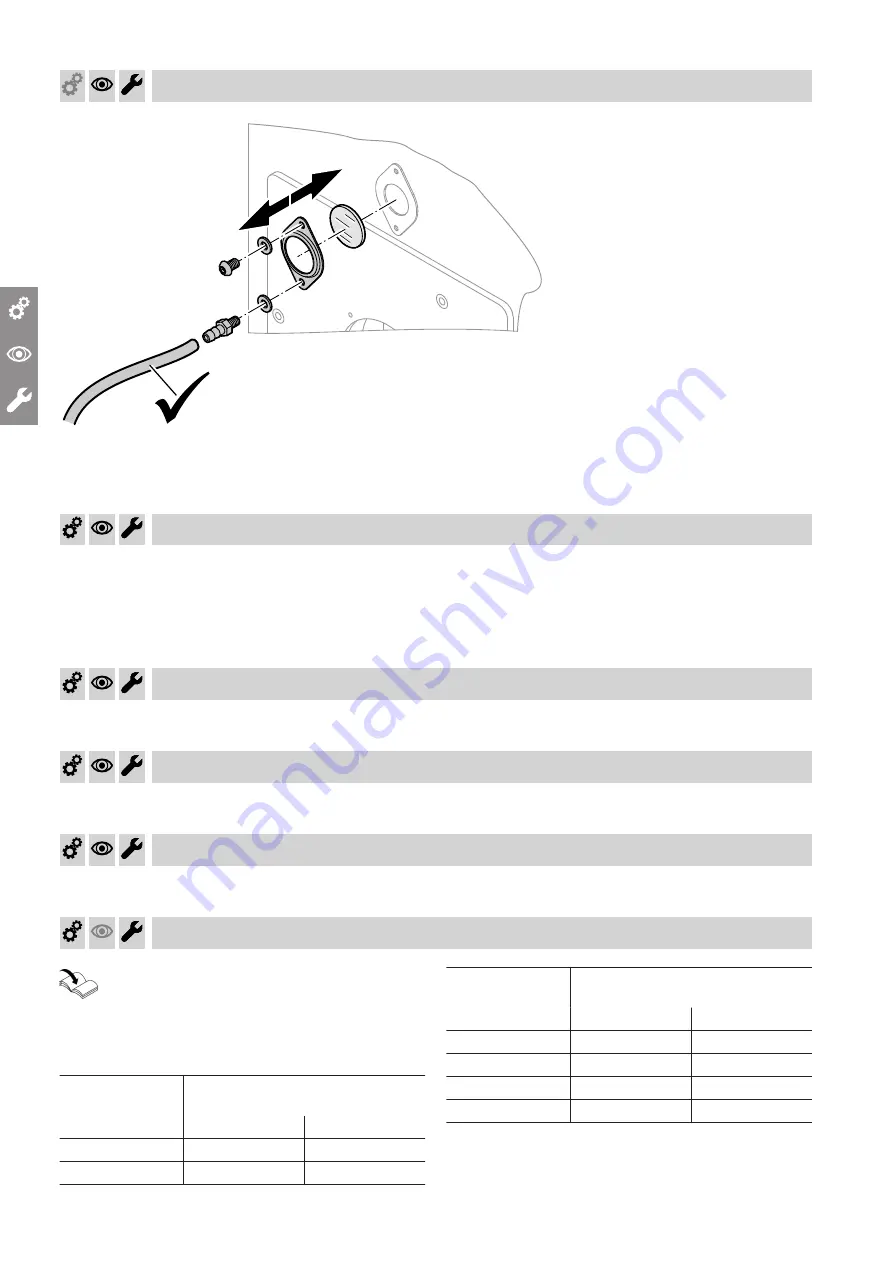

Check the gaskets and hose connection for tightness.

Checking the mixer for ease of operation and tightness

1.

Remove the motorised lever from the mixer han-

dle.

2.

Check the mixer for ease of operation.

3.

Check the mixer for leaks. In the event of a leak,

replace the O-ring.

4.

Snap the motorised lever into place.

Checking the function of the return temperature raising facility (if

installed)

Checking the installation room ventilation

Checking the flue pipe for tightness

Adjusting the burner

For burner adjustment, see separate burner

documentation.

Adjust the maximum oil or gas throughput of the

burner to the rated boiler heating output.

Rated heating

output

Pressure drop on the hot gas

side (fuel oil

*2

)

kW

Pa

mbar

780

350

3.5

950

450

4.5

Rated heating

output

Pressure drop on the hot gas

side (fuel oil)

kW

Pa

mbar

1120

590

5.9

1350

570

5.7

1700

720

7.1

2000

540

5.4

*2

Values for natural gas plus around 5 %

Commissioning, inspection, maintenance

Cleaning the sight glass in the boiler door

5461424