10

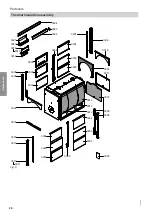

Fig. 2

1.

Remove turbulators

A

without applying force

using the turbulator extractor supplied.

2.

Clean flues

B

and combustion chamber

C

with

the brush.

Remove combustion residues with a vacuum

cleaner.

Fig. 3

3.

Use a vacuum cleaner to remove combustion resi-

dues from the flue and the flue outlet through

cleaning aperture

D

in the flue outlet.

Cleaning cover

The version of cleaning cover on the flue gas col-

lector depends on the output rating.

Checking all gaskets and packing cords on the flue gas side

Checking the thermal insulation components on the boiler door

Inserting the turbulators

!

Please note

Some burner settings and specific system condi-

tions can cause the turbulators to move forward

and be burnt as a consequence. This can also

lead to damage to the thermal insulation on the

boiler door.

Lock the turbulators in place.

Commissioning, inspection, maintenance

Cleaning the turbulators, heating surface, flue outlet and flue pipe

5461424