Installation and service

instructions

for contractors

VIESMANN

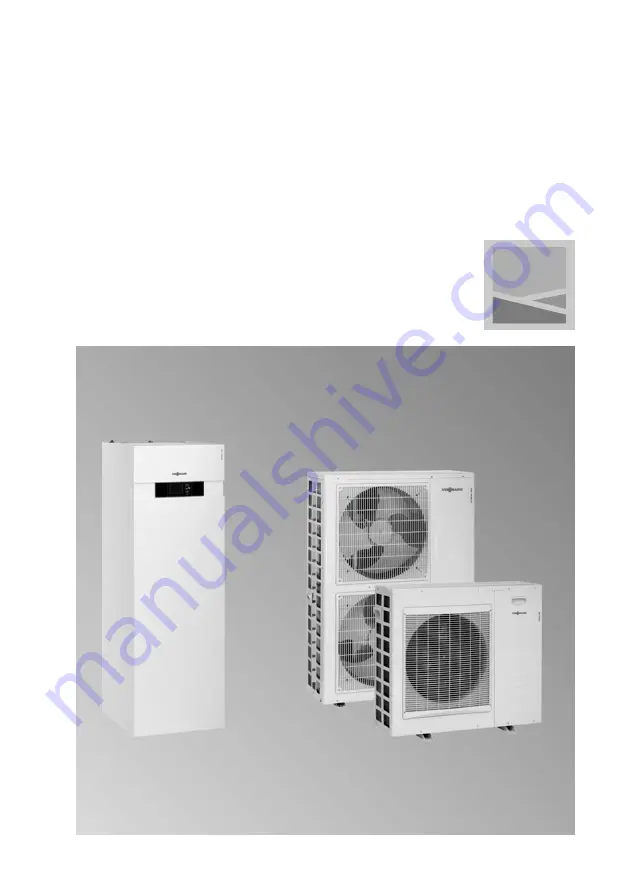

Vitocal 222-S

Type AWT-AC 221.A04 to A13, B10, B13

Compact heat pumps, split version for heating and cooling opera-

tion

For applicability, see the last page

VITOCAL 222-S

5782 201 GB

2/2013

Please keep safe.