Manual page 8

DETERMINING PROPER SPAN GAIN (F2)

Note: Normally done from factory.

OVERVIEW

The Span Gain parameter found in F2 of the Setup Menu is directly related to the ADC (Analog to Digital Converter) integration time. This

means that the lower the setting, the higher the number of measurements per second. A span gain setting of

25

produces about 25 to 30

measurements per second, while a span gain of

200

produces only about 3 or 4 measurements per second.

There is really no wrong setting for span gain – except in two cases. Using a low setting for a high resolution, low output system could yield

instability. Using a high setting in a high output system could yield non-linearity.

SETTING THE INITIAL VALUE FOR SPAN GAIN

1. Determine the number of desired external graduations and choose the corresponding value listed in Table C-1 under the number closest to

your full-scale input range in millivolts.

2. Enter the Setup Menu and save this number for the Span Gain parameter in F2.

3. Perform a system calibration. If the calibration proves unsuccessful, or you wish to view the internal counts, proceed to the next set of

instructions.

VIEWING THE INTERNAL COUNTS

1. Enter the zero calibration menu (F16) and follow steps 1 to 3,

but do not save the zero point.

2. After pressing

ZERO

to zero the offset, place the test weight(s) on the platform. The displayed count is the internal count. If the count

remains on zero, check your load cell connections.

3. At full scale, the displayed count should be a minimum of 2 times the desired external graduations. However, for maximum stability, a ratio

of 6:1 or higher is recommended.

4. If the displayed count is large enough, remove the test weight(s), re-zero the indicator if necessary, and proceed with the calibration. If the

displayed number is

not

large enough, increase the Span Gain to the next highest choice in the Setup Menu and re-calibrate.

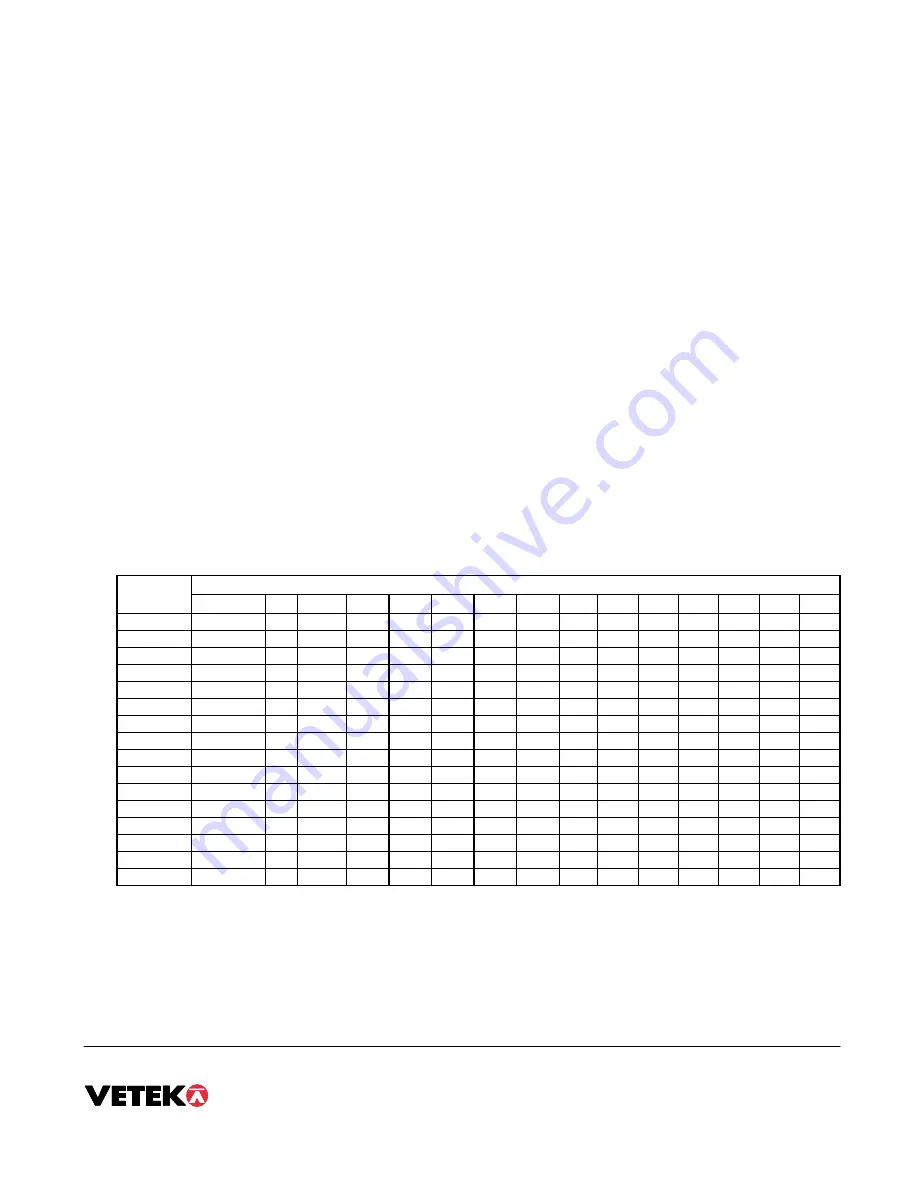

External

Full Scale Input Range (mV/V)

Grads

0.2

0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0

500

75

50 25 25 25 25 25 25 25 25 25 25 25 25 25

1,000

150

75 50 50 25 25 25 25 25 25 25 25 25 25 25

1,500

200

100 75 50 50 50 25 25 25 25 25 25 25 25 25

2,000

–

150 75 75 50 50 50 50 25 25 25 25 25 25 25

2,500

–

200 100 75 75 50 50 50 50 50 50 25 25 25 25

3,000

–

200 150 100 75 75 50 50 50 50 50 50 50 25 25

4,000

– –

150 150 100 75 75 75 50 50 50 50 50 50 50

5,000

– – 200 150 150 100 100 75 75 75 75 50 50 50 50

6,000

–

– –

200 150 150 100 100 75 75 75 75 75 50 50

8,000

–

– – –

200 150 150 150

100 100 100 75 75 75 75

10,000

–

–

– – –

200 200 150 150 150 150 100 100 100 75

12,000

–

–

– – – –

200 200 150 150 150 150 150 100 100

15,000

–

–

–

– – – – –

200 200 200 150 150 150 150

20,000

–

–

–

–

– – – – – – –

200 200 200 150

30,000

–

– – – – –

– – – – – – – – –

40,000

–

– – – – – – – –

–

– –

– –

–