24

20303735

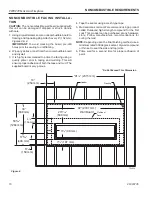

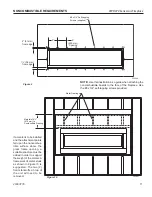

VWDV70 Series Gas Fireplace

FIrepLace InstaLLatIon

checK Gas type

Use proper gas type for the fireplace you are installing.

If you have conflicting gas type, do not install fireplace.

See dealer where you purchased the fireplace for proper

fireplace for your gas type or conversion kit.

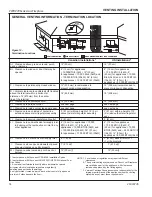

InstaLL Gas pIpInG to FIrepLace

LocatIon

InstaLLatIon IteMs neeDeD

Before installing fireplace and burner system, make sure

you have the items listed below.

•

External regulator (supplied by installer)

•

Piping (check local codes)

•

Equipment shutoff valve*

•

Sealant (resistant to propane/LP gas)

•

Test gauge connection*

•

Sediment trap (recommended)

•

Tee joint

•

Pipe wrench

•

Approved flexible gas line with gas connector (if

allowed by local codes — not provided)

* A CSA design-certified equipment shutoff valve with

1/8" NPT tap is an acceptable alternative to test gauge

connection. Purchase the CSA design-certified equip-

ment shutoff valve from your dealer.

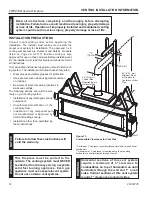

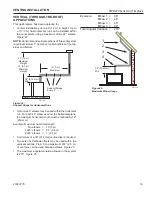

For propane/LP connections only, the installer must supply

an external regulator. The external regulator will reduce

incoming gas pressure. You must reduce incoming gas

pressure to between 11 and 13 inches of water. If you do

not reduce incoming gas pressure, burner system regula-

tor damage could occur. Install external regulator with the

vent pointing down as shown in

Figure 35.

Pointing the

vent down protects it from freezing rain or sleet.

W

arn

In

G

a qualified installer or service person must

connect appliance to gas supply. Follow

all local codes.

caut

Ion

For propane/Lp units, never connect

fireplace directly to the propane/Lp supply.

this burner system requires an external

regulator (not supplied). Install the external

regulator between the burner system and

propane/Lp supply.

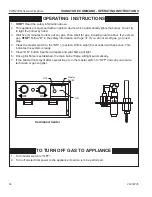

FP1977

external regulator

Figure 35 -

External Regulator with Vent Pointing Down

(Propane/LP Only)

FP1977

External

Regulator

100 gallon (min)

Propane/LP Supply

Tank

Vent Pointing

Down

caut

Ion

use only new black iron or steel pipe.

Internally tinned copper or copper tubing

can be used per national Fuel code, section

2.6.3, providing gas meets hydrogen sulfide

limits, and where permitted by local codes.

Gas piping system must be sized to provide

minimum inlet pressure (listed on data plate)

at the maximum flow rate (Btu/hr). undue

pressure loss will occur if the pipe is too

small.

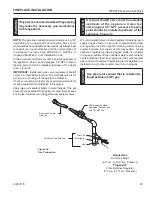

When using copper of flex connectors use only fittings

approved for gas connections. The gas control inlet is

3/8" NPT.

The gas control is equipped with a captured screw type

pressure test point, therefore it is not necessary to provide

a 1/8" test point up stream of the control.

Always provide a union when using black iron pipe so

the gas line can be easily disconnected for burner or fan

servicing. Refer to gas specifications for pressure details

and ratings.

The fireplace valve must not be subjected to any test pres-

sures exceeding 1/2 psi. Isolate or disconnect this and

any other gas appliance control from the gas line when

pressure testing.