20303735

23

VWDV70 Series Gas Fireplace

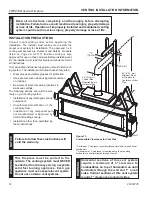

4. Horizontal runs of flexible vent shall be supported

at maximum 2 foot intervals; vertical runs, five feet

intervals. Metal strapping, properly secured, is an

acceptable means to support the flexible vent.

5. Flexible vent spacers are to be installed at inter-

vals prescribed by the flexible vent manufacturer;

and in such a way as to maintain concentric inner

and outer vent spacing.

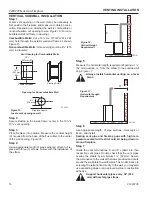

D. Attaching flexible venting to vertical termination

assemblies.

1. When using Duravent pipe, an Vermont Castings

Group flex-to-pipe adapter (FPA) and/or rigid pipe

section(s) is required to connect the flexible vent

assembly to the vertical termination by using

three self-penetrating screws.

2. Review

Figure 33

and corresponding instruc-

tions for proper overlap, clamp and screw place-

ment.

3. Three each self-penetrating screws are drilled

opposite one another and below the gear

clamp.

4. Use only listed and approved terminations and

accessories, installed per the installation instruc-

tions and

Figure 32

.

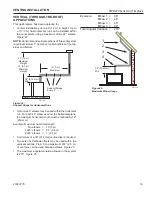

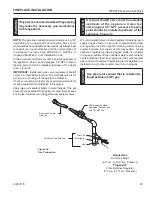

FLex Vent InstaLLatIon

Termination

Cap

Storm Collar

Roof Support

Flashing

Rigid Pipe

Length

Flex to Pipe

Adapter

Firestop

UL1777 Flex

PIpe

DVFF8A/8

Adapter

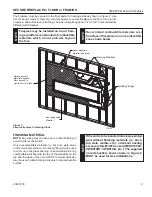

Figure 32 -

Typical Vertical Flex Vent Installation

FP1975

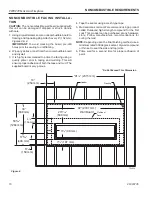

pipe connection

Screws

(3 Places

equidistant

just above

gear clamp)

Rigid Pipe Length

Flex to Pipe Adapter

Gear Clamp

1

C\v

" Flexible Pipe and Adapter

Outer Collar Overlap

UL1777 Flex Vent

Figure 33 -

Typical Pipe Connection

Gear Clamp

FP1976

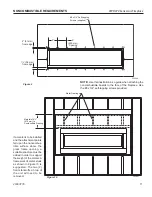

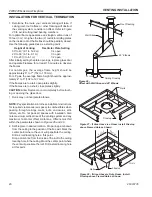

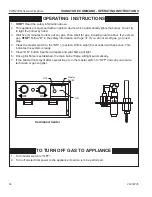

horizontal flex

Screws

(3 Places equidistant just

above gear clamp)

Gear Clamp

UL1777 Flex Vent

1

C\v

" Flexible Pipe and

Collar Overlap

Vermont Castings

Group Horizontal

Vent Termination

Figure 34 -

Typical Horizontal Flex Vent Installation

FP1974

E. Installing flexible venting to horizontal termination

assemblies.

1. Connect the 5" flexible vent to the horizontal

termination as in

Figure 34

.

2. Connect the 8" flexible vent to the termination

ring as in

Figure 34

.

3. Review

Figure 34

for proper overlap and clamp

placement.

4. Three each self-penetrating screws are drilled

opposite one another and below the gear

clamp.

5. Use only listed an approved terminations and

accessories, installed per the termination instruc-

tions and

Figure 34

.