VSW40 Wood Stove

10

20300060

INSTALLATION

FLOOR PROTECTOR

Installation on a Concrete Floor

An appliance mounted on a concrete floor does not require

floor protection.

Carpeting and any other combustible material shall not

cover the floor protector.

If a combustible surface is applied to the concrete floor,

a clearance must be maintained equivalent to the area

reserved for the floor protector.

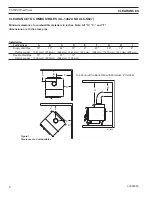

Figure 4

Installation on a Combustible Floor

If the appliance is to be installed on a combustible floor

or a combustible floor covering, it must be installed on a

non-combustible floor protector. The pad must be installed

beneath the appliance extending 18" (457 mm) in Canada,

16" (406 mm) in the U.S. on any side equipped with a door,

and 8" (203 mm) on all other sides. In the U.S. the pad

must cover any horizontal chimney connector runs and

extend 2" (51 mm) beyond each side.

2” (51 mm)

2” (51 mm)

8”

(203 mm)

8”

(203 mm)

* 18” (457 mm)

** 16” (406 mm)

8”

(203 mm)

ST1059

SSW20 floor protection

* Canada

** US

ST1059

Figure 4 -

Installation on a Combustible Floor

ChIMNEY

Refer to chimney and chimney connector manufacturer’s

instructions.

Contact your local building authority for approved methods

of installation

1. This appliance requires a masonry or pre-manufactured

chimney listed to ULCS629 (Canada) and UL 103 HT

(USA) sized correctly.

2. If a masonry chimney is used it is advisable to have your

chimney inspected for cracks and check the general

condition before you install your unit. Re-lining may

be required to reduce flue diameter to the appropriate

functional size.

3. The chimney should extend at least 3' (914 mm) above

the highest point where it passes through the roof, and

at least 2' (610 mm) higher than any portion of a building

within 10' (3 m).

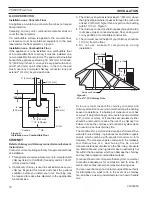

Figure 5

4. The chimney connector shall not pass through an attic,

roof space, closet, concealed space, floor, ceiling, wall

or any partition of combustible construction.

5. The minimum overall height of your chimney should be

15' (5 m) from the floor.

6. Do not use makeshift compromises during

installation.

0 to 10’

2’ Min.

3’ Min.

0 to 10’

2’ Min.

3’ Min.

ST1012

2 3 10 rule

Reference Point

ST1012

Figure 5 -

The 2'-3'-10' Chimney Rule

At the very least, inspect the chimney connector and

chimney at least once every two months during the heating

season to determine if a buildup of creosote or soot has

occurred. If a significant layer of creosote has accumulated

(1/8" (3 mm) or more], or if soot has accumulated, either

should be removed to reduce the risk of a chimney fire.

Failure to keep the chimney and connector system clean

can result in a serious chimney fire.

The conditions for a chimney fire develop as follows: When

wood is burned slowly, it produces tar and other organic

vapors which combine with expelled moisture to form

creosote. The creosote vapors condense in the relatively

cool chimney flue of a slow burning fire. As a result

creosote residue accumulates on the flue lining. Creosote

is a flammable and, when ignited, make an extremely hot

fire within the flue system which can damage the chimney

and overheat adjacent combustible material.

To reduce the amount of creosote that may form, remember

to provide adequate air for combustion and to strive for

small, intense fires rather than large smoldering ones.

You can never be too safe. Contact your local fire authority

for information on what to do in the event of a chimney

fire, and have a clearly understood plan on how to handle

one.